Wooden staircase between floors. Drawing of a wooden staircase to the second floor

The interfloor staircase is an important part private house. It should be comfortable for adults and children. In addition, it is necessary to provide for the possibility of lifting large objects along it. The most popular materials for making stairs inside the house are wood and metal. In this article we will look at how to make a staircase to the second floor in a private house with your own hands.

Requirements for interfloor stairs

For comfortable and safe operation stairs inside the house, it must meet a number of requirements:

- high-quality lighting of all spans;

- the width of the flight of stairs must be at least 80 cm;

- a staircase with 3 or more steps is equipped with railings, the height of which is at least 90 cm;

- The inclination of the stairs is also regulated; the degree of rise is 38-45°. The ascent to the attic or attic can be equipped with a staircase with a degree of inclination of 65-74°;

- for ease of ascent, it is advisable to make the number of steps in a flight an odd number.

Advice: before making the stairs to the second floor in wooden house, you need to calculate the load-bearing capabilities of interfloor ceilings. Most often, lightweight metal or completely wooden structures are installed.

Wooden staircase. Features of the material

The leader in popularity for the manufacture of interfloor stairs in country houses and multi-level apartments are made of wood. It has been used for many centuries. But in order for a product made from it to be durable, it is important to observe a number of nuances.

- The wood has a beautiful appearance and does not require expensive finishing. Depending on the type of wood, it has different pattern and natural shade. All this can be played out and preserved by covering the material with transparent varnish. Thanks to the ability to artistically process wood, real masterpieces are created from it in the form of carved balusters and other decorative elements. In addition, a wooden staircase creates additional comfort in the room and is indispensable when design solutions in country style.

- Wooden interfloor staircase It is especially preferable if the floor is made of logs. The low weight of the structure in this case is an important argument. In addition, to install it you will not need any equipment (faucet, automixer). But it's worth considering specific gravity different types of wood, so an oak structure is almost similar in weight to a metal structure of the same size.

- Can be installed even if finishing repairs in the flight of stairs is finished. Since there is no dirty work involved, which is inevitable when welding metal stairs or pouring concrete steps.

- Relatively low price compared to others. Wood is optimal when combining price and quality. The cheapest will be pine, but it can release resin. From budget options It is better to give preference to birch.

Choosing wood for interfloor stairs

- Premium wooden stairs have a higher price. This is a staircase that becomes the central decorative element of the house. For its manufacture, only expensive and especially beautiful wood is used, such as oak, ash or beech. It is performed using carved technique, providing the structure with big amount decorative elements.

- In the ranking of beautiful and durable, beech and oak share first place. But ash surpasses them in the beauty of the design, while not inferior in density.

- In the cheaper price category are larch, birch and pine. They have lower strength characteristics. But the main argument when choosing them is lower, and as a consequence, affordable price most home owners.

- Pine is the softest wood, so it is often used for temporary stairs. But beautiful balusters are made from it, which will decorate the structure for a long time. for long years. But to create the steps and frame, you should choose birch.

DIY wooden staircase to the second floor

Materials and tools for wooden stairs

- It is best to buy ready-made steps, but if this is not possible, then timber with a cross-section of 40 mm is purchased for their manufacture;

- board 40 mm thick in quantity equal to the calculated amount for the project;

- beams 30 mm thick for treads;

- beams 25-30 mm for risers;

- block for strings and stringers 50x250 mm;

- balusters and handrails;

- wood screws;

- jigsaw;

- screwdriver;

- chisel, hammer;

- level, plumb line, square, tape measure, pencil;

- sanding paper, brushes and finishing material.

Calculation of interfloor stairs

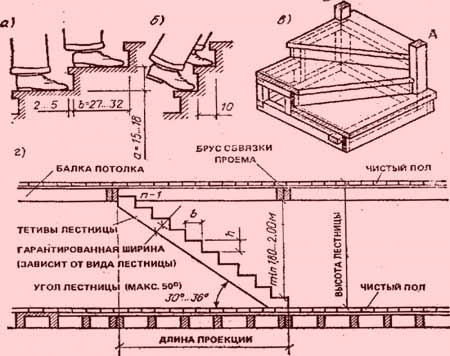

- First you need to decide on the angle of inclination. As stated above, the preferred tilt angle is approximately 40°. But most often the calculation has to be made from the existing dimensions allocated for the flight of stairs and ceiling height.

- The minimum width of a flight of stairs is 80 cm, but 125-150 cm is considered comfortable.

- Now there are many online calculator ov calculation of stairs. There it is enough to fill in the desired ceiling height and the desired height of the steps (15-20 cm). And the program will produce a 3D model with all dimensions.

Wooden staircase design to the second floor photo

How to make a straight staircase to the second floor

Let's look at the example of building a simple straight staircase without winder steps or landings.

- Installation of stringers. Take a beam, measure the total length and cut it off. You also need to immediately cut off the width of the tread (the thickness of the step itself, usually 4 cm). In the general calculation, the width of the steps was not initially taken into account, and if this does not play any role in the future, then for the first step this is an important point.

- Cutting openings for steps in a stringer. This is done using a square. It marks the height of the riser and the width of the step. The marks are transferred to the stringer and cut out with a jigsaw. The cut areas are sanded or milled, rounding the edges. Then the stringers are placed on permanent place, securing it to the floor from below, and from above to the opening in the ceiling using anchors. It would be good if the ladder was attached to the wall along its entire length.

- Installing the bowstring. Bowstrings are measured according to the length of the stringers. Apply to the stringers and mark the places where the steps are attached. Recesses are made in the title for them.

- Fastening the risers. They are made from a beam of appropriate width. It is sawn into separate elements, sanded and attached with self-tapping screws to the stringer. To prevent the fasteners from being noticeable, you need to tighten them slightly, deepening the caps a little in order to putty them later.

- Installation of steps. Beams or boards are laid on the risers, and after fastening they are sanded. But there is a high risk that the wood will shrink, which will lead to cracks and creaking. Therefore, it is better to buy ready-made steps, made of laminated wood.

- Fastening the railings. Then balusters or other railings are attached to the steps using studs. Handrails are placed and screwed on top.

DIY installation of stairs to the second floor video

Finishing of a wooden staircase

Wood - full grade finishing material. Finishing work, often come down to only emphasizing the design and applying a protective layer.

If the material is damaged, cracked or chipped, they are puttied to match the color of the wood. After coating with tinted varnish or stain, these defects become invisible.

Stages of work

- Upon completion of the staircase assembly, everything wooden elements sanding. Then wipe with a damp cloth to completely remove all dust.

- If there are defects, they are immediately filled with putty and left for a day until the composition has completely hardened.

- Then you can go in two ways: first, tint the stairs with stain, and then apply a protective transparent varnish, or ask the store to tint the varnish. The second option is preferable, since the work will go faster and the color will be the same on all elements.

- The varnish for the treads is chosen to be very wear-resistant - floor or deck. After applying 1 layer and its complete drying, the steps must be sanded with fine sandpaper. Then a second layer of varnish is applied.

Tip: it is quite difficult to apply tinted varnish evenly; even when using a brush with very fine bristles, traces of strokes will be noticeable. It is recommended to use a spray gun.

Metal interfloor staircase

To make a ladder from metal you need to have welding skills. In addition, this design is more complex and expensive to implement. But it has a number of significant advantages over its wooden counterpart:

- high strength and longer service life;

- technical characteristics ensure resistance to heavy loads;

- reliability of connection points;

- the ability to create various designs;

- allows you to extend the installation process. Yes, during repair work In order not to pollute the steps, you can only climb along the frame. And after finishing install steps;

- the metal frame of the staircase will guarantee that creaking will not appear over time.

Types of metal interfloor stairs

The appearance of the staircase depends only on the imagination and interior design into which it should fit harmoniously. But its design depends on the location.

- Installation location. It is convenient to use the stairs inside the house all year round and it becomes decorative element. Their outdoor location allows them to save living space; they are often placed to be lifted from the balcony to the attic floor.

- Manufacturing methods. Most often, welded stairs are made. The easiest way is to make them yourself right on the spot. Forged structures are more elegant, but are made in workshops in advance.

- Finishing. In stairs without finishing, it is stipulated that the frame will be visible, which means it must be made of very high quality from an aesthetic point of view. With finishing, the flights of stairs are completely closed on all sides; it is not uncommon to set up a room underneath with a door for storing things or food.

- By build type. One-piece, they are sold in ready-made sections and assembled on site. In this case, its exact dimensions must be known at the stage of designing the house. Prefabricated ones consist of a large number of parts and connecting elements, which allows you to create a structure of the desired height.

- Difference in design. Marching ones are either a staircase with a turning platform or with winder steps. Spiral staircases are the most compact, since the flight is located around one central support pillar.

DIY metal interfloor staircase

Before assembling the stairs to the second floor, you need to prepare everything necessary tools and materials:

- welding machine;

- grinder, drill;

- square, level;

- electrodes, metal screws, cutting and cleaning discs for grinders;

- channel, metal pipe;

- metal corner;

- sheet metal.

Tip: the quantity and characteristics of the material depend on the type of staircase structure, the number of steps and finishing. Thus, stone is much heavier than wood, and when finishing it, the staircase frame must be stronger than when facing it with wood.

Theoretically, the ladder can be made in two ways: welded in advance and already in finished form installed on site or manufactured in stages directly in the installation area. The second option is preferable, as it allows, if necessary, to make adjustments.

Stages of work

- First, the type of frame is determined. If there are winder steps, what will be their location (rotate by 90° or turn by 180°).

- Using the program and known dimensions, a sketch is created. It is recommended to entrust this stage to a professional designer.

- In accordance with the project, the required amount of metal is purchased, and if necessary, it is immediately cleaned from scale and rust with a grinder. Drawings of the elements are transferred to it and sawed. At this stage it is important to mark all parts of the structure.

- If there is a platform, then first its frame is made and installed in the flight of stairs. Next, beams are mounted from the floor to it, acting as stringers.

- Next, the required number of identical fillies are produced at once - these are triangular elements that will serve as a support for future steps. They are welded along the entire length of the stringer. It is very important to position them correctly, so first you just need to grab them pointwise in a couple of places, check the evenness with a square and only then make a quality seam. They can also be welded to the frame or secured with bolts. The work is carried out from the bottom up, installing the lower fillies, placing a board on them and standing on it, and so gradually moving up to the top.

- If it is necessary to achieve greater rigidity of the steps, then a steel corner is welded between the fillets, which also acts as a support for the step.

- Then comes metal processing. All seams are cleaned, then treated with acetone, an anti-rust agent and primed. After that it is painted.

- Attach the steps to the bolts from below. Then the railings and decorative elements are installed.

Layout of the staircase to the second floor in a private

Finishing of a metal staircase

Tiling a metal staircase:

- Laying the tiles begins from the bottom up. First, it is attached to the riser between the floor and the first tread. Then the tiles are laid along the width of the entire first step and only then the next tread is attached. This method allows for the most efficient application of glue and the absence of sawed edges of the tiles;

- since a metal staircase will vibrate when walking on it, the tile adhesive must be special and of high strength;

- It will not be possible to complete all the cladding in one stage. Since you will have to leave room for walking on the edge until the tile adhesive has completely set in other areas.

Cladding a metal staircase with wood:

- attaching a wooden tread to a metal step from below will be the most the best option, since the place of fixation will be invisible. To do this, the metal step is pre-drilled in 8 places (4 on each side of the center, at a distance of 25 cm from each other). A wooden step is placed on top and attached to the bottom through the holes with self-tapping screws;

- If fastening from below is not possible, you will have to drill through the wooden step from above along with the metal. To do this, it should be firmly fixed to a metal platform. To hide the heads of the screws, drill a 5 mm recess from above with a drill larger diameter. The tread is fastened with metal screws, and the head is puttied. Or use special wooden overlays.

Interfloor concrete staircase

- Concrete stairs are very heavy and can only be erected in houses with reinforced concrete floors.

- They are built immediately after the frame of the house with the roof is ready.

- Once the solution has set, it can be used.

- With time concrete stairs they will not begin to creak like wooden ones, and when stepped on, vibrations will not form like iron ones.

- Due to their solidity, such stairs are considered safer, and if the cladding is damaged, it can be easily repaired.

- But it will not be possible to make a staircase from concrete in a small opening.

Step-by-step instructions on how to make an interfloor concrete staircase

- When all the calculations have been made, according to the project, the formwork of the entire flight of stairs is done. It is made from boards 20-30 mm thick.

- Reinforcement is laid inside the future steps. It can be knitted from a metal or fiberglass rod.

- The lower stage is poured first. While the solution is soft, it is pierced with a metal trowel to remove air bubbles and compact it as much as possible.

- After this, the poured step is covered with film and a board longer than the steps is placed on top so that it rests on the formwork and can be stepped on to fill the next step. The entire staircase is built in this way.

Finishing of concrete stairs

- After dismantling the formwork, the staircase has a massive and unrefined appearance. Careful finishing will be required not only of all elements (steps, risers), but also of all places adjacent to the walls.

- The choice of material depends on the configuration of the staircase. If it is straight, then there will be no problems, but if there are winder and turning steps, facing material should cut easily.

- Also, the coating of the treads themselves must be non-slip and resistant to mechanical stress.

- IN Lately It became popular to finish stairwells with the same material that was used on the floors of both floors.

- The degree of noise is also important. If wooden steps or covered with carpet almost completely absorb the noise of footsteps, then stone or finished tiles, on the contrary, can enhance it.

Using roll material, it is worth gluing it very carefully. If even a small fragment comes off, it can cause a fall. Most often, this is carpet with a high degree of abrasion resistance (wool carpets are not suitable for stairs). It is allowed to veneer the steps cork covering, but not rolled, but with greater thickness in mats.

Staircase drawings presented on the Internet make it easy to select suitable option. But every house has its own design features. That's why ready-made solutions may not fit. And a drawing drawn up with your own hands, according to which the staircase will be installed in the future, will become a special source of pride for the owner in front of relatives, neighbors, and friends.

Before starting design, you should decide on the type of structure. The following options can be roughly distinguished:

An important option for designing or selecting a drawing is load-bearing structure under the stairs:

The material is selected taking into account the planned structure and overall interior design. There are no restrictions in this area. A combination is often used: metal, as a load-bearing part of the structure, and glass, wood, ceramic tile, others as steps.

Drawing data

To begin with, determine the location of the future structure and make the following measurements:

Before developing a drawing, you should carefully study building codes for stairs:

Competent drawings of stairs to the second floor can be made only on the basis of the listed parameters and further calculations. Each type of design has its own characteristics.

Drawing of the staircase to the second floor

Drawing of the staircase to the second floor Methods for obtaining a drawing

There are several ways to compile project documentation:

Everyone chooses their own method of obtaining design documentation. If you have the strength and time, you can manually prepare a diagram and details of the staircase.

Basic formulas for calculation

To obtain additional data when drawing up a drawing, several basic formulas are used.

When making calculations, it is recommended to check the data with technical standards for stairs. If necessary, adjust the height and depth of the steps. But also when making calculations and drawing up a design drawing, do not forget about the thickness of the material. Otherwise, the work done will not be completed correctly.

Staircase drawings

If you decide to independently prepare a drawing and design calculation, then you should understand that each type of staircase has its own design features.

Direct

The simplest type of design, since making a drawing and calculations is not difficult even for an inexperienced carpenter.

The length of the span, the number of steps, their depth and height are calculated. Determined by the width of the stairs. The number of steps determines how many marches there will be. If the number is more than 18, it is recommended to arrange the site. It is placed in the middle, at the top or bottom of the stairs.

Diagram and drawing of a straight staircase

Diagram and drawing of a straight staircase In addition to the main projections, structural details should be carefully calculated and drawn. For straight marches, the following fastening methods are used: stringers, bowstring, bolts.

Turning stairs with landings

Staircases of this type can be two or three flights. The placement of platforms largely depends on the parameters of the room and the calculated data on the height of the passage and the width of the opening. Designs with the transition located at the bottom, in the middle and at the top are allowed.

The first two options are considered optimal in terms of comfort and safety, as they are clearly visible from different height levels.

When designing, it should be understood that the dimensions of the site should not be less than the width of the connected span.

Recommended fastening systems: stringers, bowstring, bolt combined with a support post. Calculations are carried out using previously presented formulas.

Stairs with winder steps

These designs are difficult to independent design. It's better to trust the professionals. If you still decide to use your own strength, you can use design programs or an online calculator that will automatically produce a drawing and details.

But you will have to manually link the resulting diagram to the floor plan.

For manual design, you can use the proportion method. There are three more methods (Danish, sweep, raising lines), but they are more difficult to perceive and design.

For manual design, you can use the proportion method. There are three more methods (Danish, sweep, raising lines), but they are more difficult to perceive and design. Example of a staircase with winder steps

The main problem in design is to calculate the shape and number of winder steps. Their configuration is sometimes different.

The fastening system is similar to the previous version.

Screw

How to do data calculation for spiral staircase? Yes, it follows a different formula, but the basic requirements for ergonomics remain the same. For convenience of calculation and design, we will use an example. Opening height H = 2800 mm (2.8 m), staircase width S = 1000 mm (1 m), support column diameter d = 200 mm (0.2 m).

Calculation of design data and building codes allow you to most accurately develop drawings and detailing of stairs of any type. For complex shaped structures with winder steps, it is better to turn to professionals. They will select and install the most suitable option.

Today, private country houses are built mainly on two or three floors. And to go upstairs, you need a ladder. Making an interfloor staircase is not an easy task, requiring special knowledge and skills. We need not just any staircase, but a structure that will be beautiful, durable, and safe. This ladder will last for quite a long time. Often in country houses and dachas, stairs are made of wood. Wood is environmentally friendly pure product

and therefore is widely used in construction. Metal, concrete, plexiglass, ceramics and all sorts of combinations thereof are also used. DIY making wooden stairs

There are many types and variations of wooden stairs, each with its own characteristics. The space where the staircase will be installed is also taken into account; it can be limited or spacious.

Types of stairs that exist in architecture:

- Marching stairs are probably the most common type; they can be one or two flights;

- Spiral staircases - this option is convenient when space is limited;

- Combined stairs - they consist of two or more types of stairs.

Before choosing one or another staircase, you need to evaluate your capabilities. It is best to start by choosing a simple straight staircase, but made of high-quality and reliable material. The space of the house has a certain role, so that after reconstruction, the staircase does not take up more than half Houses. For this you need your own scheme. You must first make measurements and calculations. And also for making staircase structures yourself, you need to have the appropriate tools, lumber and experience working with wood.

How to make a wooden staircase: drawing of a marching variety

It is much easier to mount a staircase with your own hands than a spiral or spiral staircase. This is a simple straight staircase with steps leading to the second floor. The number of steps should not exceed 10. If this happens, then the stairs are divided and a platform is installed between them. It can be: single-flight, two-flight, three-flight or multi-flight. This staircase takes up a lot of space in the house. To save space, a rotating type product is constructed. They can have a rotation angle of 90 degrees and are called quarter-turn, or half-turn with a rotation of 180 degrees.

How to make a wooden staircase, a drawing for it, and a project? This is a question that requires competent calculation of the number of steps, flights, the staircase itself and the space it occupies. It is also necessary to think over the design and lighting of the staircase in advance.

All this can be done if you have the materials from which your staircase will consist and the tools necessary for the work. But the most important thing is what parts your staircase will consist of.

The main elements that make up the staircase:

- steps;

- Risers;

- Kosour or bowstring;

- Railing;

- Balusters;

- Fasteners.

Calculation of a wooden staircase using an online calculator

All houses differ from one another in their architecture, size, and layout. Therefore, there cannot be one template for all houses.

The calculation of a wooden staircase consists of several stages, combining which together you can make required drawing with dimensions. The drawing for each staircase is drawn up individually.

You can make an error-free calculation of the stairs using a unique program - an online calculator. This program, by processing the entered data, can provide any staircase project and its 3D dwg model. To ensure that the staircase is comfortable, beautiful and practical to use, and also does not cause injuries, you need to comply with basic standards and rules.

Main parameters for calculation:

- The number of steps must be from 3 to 16 and it must be odd;

- The height of the steps is from 12 to 20 cm, width – 23 – 25 cm;

- The slope of the stairs is 30 - 35 degrees, can be increased to 45 degrees;

- The railing should be at least 90cm high, and if you have children, you can increase the height to 150cm.

Many owners want to build a staircase with their own hands, so that it suits their taste and is safe. And do it without unnecessary waste precious time. This is why there is such a program as a calculator.

We are developing a drawing of a wooden staircase to the second floor

Making a drawing of a wooden staircase with your own hands is one of the most reasonable decisions. The ladder must be used for both walking and carrying various items. And for this, the design must be comfortable and durable.

A drawing for the second floor of a wooden staircase can be made by defining the parameters staircase. That is, the space that you can allocate for the stairs leading to the second floor.

Then we draw a sectional diagram of the staircase. This drawing determines the position of the upper and lower steps.

The main thing to note on the drawing:

- Slope angle;

- Distance of the upper tier to the ceilings and floor;

- Opening dimensions;

- Number of stages with all parameters;

- The number of marches and the size of the area between them.

Do-it-yourself calculations of a wooden staircase (video)

It is necessary to develop a drawing of the staircase that leads to the second floor together with the design and layout of the house itself. Then your staircase will fit perfectly into the interior of the room and will match all necessary requirements security.

Recently construction country house very often it is not limited to one floor. In order to expand the space, a second one is built or insulated and made suitable for comfortable stay condition of the attic room. This means that you can’t do without a staircase in the interior of the first floor.

A do-it-yourself staircase to the second floor can easily be assembled from a ready-made kit, which can be purchased from companies specialized in the development and manufacture of this interior functional element. In the catalogs offered, you can choose a staircase that will ideally fit into the decor of both floors, and will be comfortable and safe for all family members to ascend and descend.

You can try to build a staircase yourself, but in this case it is necessary to do so, since if the design is not well thought out, a familiar element of the house may well become a traumatic “simulator”.

In addition, you need to decide what role the staircase will play in the interior. It may be completely invisible and not be decorative decoration room, or can become the center of the composition around which the entire design of the room will be built.

Therefore, to choose a suitable instance, it is better though would schematically draw the staircase you wanted would see in your home, but you can already find ready-made option and adapt it to a specific room.

Before choosing a staircase model, you need to know how it is designed and how to calculate its correct parameters.

The main components of the stairs

The design of a staircase has many components, some of them are mandatory, while others may not be included in the design of some types of this structure.

So, a staircase cannot do without steps and supports that support them - these are the main elements of the most simple designs interfloor stairs.

- The step itself consists of two parts - vertical and horizontal. The first of them is called riser, and the second is called gait. The riser is a support for the step, but sometimes they do without it.

- Supports can be of two types:

— the bowstring is a beam that supports the steps from their ends;

- stringer - a beam supporting the steps from below.

- Railings are also important element stairs, although it is not present in all types. But if there are children or elderly people in the house, then there is no way to do without them.

- Balusters are vertically installed supports for railings, which most often become not only a functional part of the staircase, but also its decorative decoration. This element can be made from different materials and have different forms.

Since there are different types of stairs, each of them may have parts that are necessary specifically for a particular design.

- Stand - this element is used to construct a spiral staircase. Steps of a special shape are attached to the rack with a certain pitch, which form a spiral rising from the first to the second floor.

- Bolts are special bolts, which are also elements supporting the steps; they are attached to the wall and directly to the steps themselves. They are not used for everyone, but only for certain types of stairs.

Types of stairs

Having found out what elements the stairs consist of, you need to understand in more detail what each type of these structures looks like, installed between floors.

Marching staircase

This type of staircase is popular for any type of private home. It consists of one or more straight flights, equipped with evenly spaced steps. It is convenient to go down and up, but the disadvantage of this model is that it requires a lot of space in the room.

The most common are flight stairs

The most common are flight stairs If the staircase consists of several flights, then each of them must have at least 3 ÷ 4 and no more than 15 steps. Failure to comply with this standard may make climbing stairs uncomfortable. Typically, the number of steps in each flight is 8 ÷ 11 pieces, and special platforms are installed between flights. Their sizes are multiples medium length step.

- Marching stairs can be closed or open. The first of them have risers in the design of the steps, and the second are installed without them. Open option convenient in cases where the steps are not wide enough.

- Marching stairs can have steps attached to stringers or strings. For these parts, boards with a thickness of at least 45 ÷ 50, and better yet, even 60 ÷ 70 mm are selected.

- If a straight staircase without turns has more than 8-9 steps, then for strength it is also recommended to divide it with a platform.

- In the case when the staircase is built with a slight turn, it is called a turning one, and sometimes in this area, instead of a landing, steps are installed, which are called winders.

Winder steps quarter reversible staircase

Winder steps quarter reversible staircase - In addition to the above types, flight stairs can be:

— quarter turn– the angle of which when turning is 90 degrees, and they are located mainly at the junction of two walls;

- half-turn - their rotation has an angle of 180 degrees;

- circular models - marches successively form a 360-degree turn.

Design of staircases on rails

The name of these stairs on the rails comes from German word"bolzen", which means bolt. So it's a bolted ladder. In fact, it is a fastener in the form of a pin with threads at its ends. With their help, steps and fences are fastened together and mounted in the wall. Thanks to these devices, the design looks light and airy. The absence of risers also contributes to this.

In addition, such a model can be stretched over a certain section of the wall, or it can look quite compact. Despite its apparent lightness, the design is reliable and durable, it can withstand hundreds of kilograms, which is why ladders on bolts are becoming increasingly popular.

Despite the “airy” appearance, the ladder on the rails is very reliable

Despite the “airy” appearance, the ladder on the rails is very reliable Naturally, such a structure cannot be located in the middle of the room, since it must be attached to the wall; the main condition for installation is the strength of the material from which it is built.

It is quite difficult to calculate a staircase with rails on your own, but you can purchase it as a kit or order it from professionals to make it, depending on the specific conditions of the house.

Video: installation of a wooden staircase on rails

The installation of this structure is quite complicated, and it is better to entrust it to qualified craftsmen who can assess the possibility of its installation. Therefore, before purchasing a kit, it is best to first consult with specialists.

Spiral interfloor staircase

This design is more difficult to install, but has the advantage that it occupies the smallest area of all existing options, so it is ideal for rooms with a small area. In addition, such a staircase can be installed in any convenient location room and, if desired, make it the center of the interior composition, since the design has a fairly aesthetic appearance.

Spiral staircase - saves space, but is not always convenient for carrying large objects

Spiral staircase - saves space, but is not always convenient for carrying large objects Can be different types, but for two-story house A model consisting of a stand and wedge-shaped steps is best suited. For rack choose metal pipe or wooden support.

- The rack itself is fixed to the floor of the first floor and in the interfloor or attic ceiling.

- The steps are attached to it with the narrow side and rotated so that the overall structure resembles a spiral.

- Balusters are installed on the wide side of the steps, top part which are fixed in the handrail, repeating the spiral direction of the entire structure.

Video: installation of a spiral staircase

What is inconvenient about such a model is the fact that it will be difficult to lift or lower down some massive piece of furniture. In addition, when choosing such a model for installation, you need to know that the smaller the opening for it in interfloor covering, the steeper and more inconvenient the stairs will be.

It is not difficult to calculate the screw structure. To do this, determine the area in the room where it will be installed, and calculate its center - this will be the location where the rack will be installed. Next, the distance from the post to the border is measured - this will be the span width, i.e. length of steps.

For comfortable walking on such stairs, the size of the middle step should be at least 200 mm, and the widest part should be no more than 400 ÷ 420 mm.

It is quite possible to make and assemble such a structure yourself, if you have skills in working with wood and the ability to calculate the loads on the selected material. However, if you do not have confidence in your abilities, then it is better to entrust the work to a specialist, as it is incorrect arranged structure very dangerous.

Requirements for the design of stairs

Before you begin, you need to know the requirements for the staircase design.

Safety is perhaps the most important thing important condition. In order for it to be fully implemented, it is very important to accurately calculate all the parameters:

— the angle of inclination, the width and height of the steps, the method of fastening the first and last of them are calculated;

- if the staircase is not located between two walls, a fence must be installed, and its height must be at least 800 ÷ 850 mm;

- if there are small children in the house, the balusters supporting the handrail of the fence should not be located further from each other than 100 ÷ 120 mm;

— the width of the steps should be 200 ÷ 300 mm;

- the ladder must withstand quite heavy loads - for residential buildings they are 300 ÷ 350 kg/m²;

- the steps must not be slippery - their texture must be thought out outer covering;

— the entire structure must be securely and rigidly fixed between floors;

— it is undesirable to install the structure at an elevation angle of more than 45 degrees;

— the width of the spans cannot be made less than 850 mm, but the optimal option is 1000 ÷ 1200 mm;

- the staircase will be less dangerous if it is divided into two or three parts by platforms;

— fastenings for structural elements must be made of quality material, so you can’t save on them;

- If wooden parts are processed independently, then you need to bring them to perfect evenness and compliance with the dimensions established by the drawing or patterns.

Video: mistakes in the design and construction of stairs

Calculation of staircase parameters and production of parts

Since for self-made and installation, a marching design with steps laid on a stringer is the most affordable, as well as convenient and safe to use, so it is worth considering.

The first thing to do is to calculate the location, number and size of steps, as well as the width of the staircase span.

Calculation of staircase parameters

The calculation of the design of the flight of stairs is carried out as follows:

- The height of the room and the length of all or part of the wall - the space allocated for installing the stairs - are taken as a basis. Having reduced these values to scale, draw right triangle, in which the hypotenuse will be the staircase itself, and the legs will be the height of the rise and the floor.

An angle of 45 degrees is considered ideal for installing a staircase, but it can be changed depending on the wishes of the home owner and the area of the room.

- A comfortable tread width should be at least 200 mm, so the leg of the floor, based on its natural length, is divided by this value. The resulting number of steps is marked on the drawing.

- The height of the risers, convenient for movement, should not exceed 100 ÷ 120 mm. To calculate them, you need to divide the height of the total rise by the selected height of the risers and also transfer it to the drawing.

- Thus, you can calculate the dimensions of the stringer for laying the steps.

- The width of the stairs will depend on the preferences of the residents and the size of the room.

Video: example of calculating a mid-flight staircase

Manufacturing of staircase parts

In order to correctly manufacture parts, you need to accurately transfer the dimensions from the drawing made to the material and select high-quality, well-dried wood.

- The most difficult thing is to cut the stringers perfectly evenly, since the reliability and strength, as well as the aesthetics of the structure, will depend on this. For these load-bearing elements, choose a solid board without cracks and numerous large knots, with a thickness of at least 45 ÷ 50 mm.

- The width of the treads can be 1.5-2 cm greater than the space provided for them on the stringers, plus the thickness of the risers. The steps should be perfectly smooth with neat rounded edges, and this is also very important to take into account. For them, a board with a thickness of 30 ÷ 35 mm is selected.

- If it was planned to make the staircase closed, with risers, then they must also be done carefully. For these elements, you do not need to take a board of great thickness, since basically the entire load will fall on the stringers, and the risers will play a role supporting the structure. A thickness of 15 ÷ 20 mm is sufficient.

- It would be better to purchase balusters and handrails ready-made along with fastenings. If there are children in the house, then, for safety reasons, it is worth installing two balusters on each step. In the case when the children have already grown up, then one element supporting the handrail is enough.

Prices for various types of staircase elements

Elements of stairs

Installation of stairs

Installation of stairs is the most crucial moment after the manufacture of all structural elements, and it must be approached with maximum responsibility.

- The stringers are installed first according to predetermined marks. On the floor they are fixed to a support beam fixed in the right place, and in the upper part they are installed in the cut-out gaps in the floor beam. Sometimes, to secure the upper part of the stringers, they use metal supports installed on a beam covering the ceiling. The fastenings for these load-bearing elements are anchor bolts.

To ensure that the parts are installed perfectly evenly, during the installation process they are constantly aligned with a plumb line and the building level.

- If risers are provided, then they are screwed before laying down the tread surface.

- Then the tread panels are secured on top of the stringers and risers with self-tapping screws.

The fastening of risers and steps occurs in a complex, and proceeds down up.

- Then, when the steps are ready, you can proceed to installing the balusters.

On both sides, that is, on the floor of the first floor and at the top of the stairs, support posts are installed, which will become the border for general design handrail (railing). They will also play both a supporting and decorative role.

Balusters can be different sizes, and made from various materials, so they can be attached in different ways. Some of them are simply installed in drilled holes in steps and handrails, others are screwed with self-tapping screws, and the mounting points are closed with decorative plugs.

- , they are covered on top with handrails, which are fixed to the supporting outer posts. If necessary, another support post can be installed in the middle of the stairs.

- If three or even four racks are installed, then instead of balusters, two or three even boards (planks) fixed parallel to the course of the stairs can serve as a reliable fence.

- When the entire structure is assembled, you can proceed to surface treatment using a grinder and sandpaper. Preparation is carried out before applying protective and decorative paint coatings.

- The first layer that is applied to the wood is antiseptic compounds. They will protect the wood from rotting, mold or mildew, and from domestic insects. After this, the structure is allowed to dry completely.

- Next, the staircase can be varnished in several layers (preferably on water based) hot wax or paint.

- If it is necessary to darken the wood, it is first coated with stain or other tinting compounds, and then, after drying, a varnish coating is applied on top of them.

After drying paint coating, the staircase will be ready for use.

Photo instructions for creating a wooden staircase

Step 1 - drawing of the future design

Step 1 - drawing of the future design

Video: another interesting option for installing stairs to the second floor

If you need to install it in your house, you need to carefully calculate every step of your work and approach it with all responsibility and accuracy.

When building a house with at least 2 floors, you definitely need to think about the stairs in it. And if the house is built with your own hands, it is logical to build the stairs as well.

Various photos of stairs help to take pre-selection and clearly understand what type of lift you need. But before you start doing the work, do the math carefully. future design on strength and size, this will save time and money, because incorrect calculations (or lack thereof) will lead to numerous alterations of the original project.

Types of stairs

Exists a large number of different options flights of stairs. They differ in the material of manufacture (wood, concrete or metal), the type of rise (sloping staircase, spiral staircase, with a turn at a certain degree).

The most common is a wooden staircase. Staircases are also often constructed with a 90-degree turn. It is not uncommon for these two types of lifting devices to be combined into one.

In case of limited space, do spiral staircase made of metal. Screw view lifting allows you to save space, and making it from metal increases the strength of the structure. Concrete is used for stairs in massive buildings (for example, mansions).

What to pay attention to

In a low-rise building, without construction experience, it is better to order modular staircase, a kind of construction set where all the parts are cut out and numbered, and all you have to do is assemble them using the instructions. This is how wooden stairs are usually made.

When building a concrete staircase, in addition to pouring the frame, you will need to external finishing (beautiful stone or wood materials). It turns out to be a double waste of time and money. However, for cottages with 3 or more floors, they are mandatory according to fire safety requirements.

When making a ladder for the first time, you don’t need to swing at it right away. complex design. The simpler the model, the more likely that you will be able to successfully build this lifting device on the first try.

Pay attention to the angle of inclination of the stairs: if it is more than 45 degrees, the ladder will be considered an extension, and you can only go down it backwards. Optimal angle the rise is considered to be 37 degrees.

Wood is preferable as a material for construction, since, thanks to its properties, it allows you to correct minor construction flaws that arose due to inaccurate calculations and inexperience of the work performer.

Also, after construction, the building may settle due to loose soil, as a result the staircase can become several centimeters higher or lower than the floor, and it is easier to correct this in a wooden structure.

When constructing a lift with a turn towards, the distance between spans must be at least 100 mm.

Construction stages

Answering the question of how to make a staircase to the second floor with your own hands, there are several stages of construction.

The first stage of any structure, be it a staircase into a house or an interfloor staircase, is the creation of a project. Special attention it is necessary to pay attention to the safety of the building and its ease of use.

The structure must withstand average weight ordinary person with a fair amount of reserve. Be sure to use railings!

If they are not there, another fence must be designed to ensure the safety of descent and ascent.

Consider creating a wooden staircase with stringers

After you have designed your building, you need to prepare the materials. In our case, choose boards of suitable thickness and length, prepare balusters with railings and prepare stringers. This will be the second stage of construction.

A 4 cm thick pine board is suitable as a material for stringers. On it, mark the steps according to the pattern and cut them out with a jigsaw.

Note!

We use the resulting product as a sample for the second (and if the width of the staircase is more than a meter, then the third) stringer. Cut to size required amount steps.

Third it will go step by step assembling all the parts together. First of all, the stringers are installed in their permanent locations. Then, using self-tapping screws, the steps are attached to the stringers.

Then, using pins, balusters are placed on the steps, and handrails are attached to them. The staircase is ready!

DIY photo of the stairs

Note!