How to build a comfortable staircase. How to make a wooden staircase to the second floor with your own hands

The second floor allows you to significantly increase the area of the house without increasing the space it occupies, but without a staircase it is impossible to get to the second floor. In this article we will talk about various options staircases that are used in brick, stone, block or wooden houses, and we will also describe the sequence of actions for building a simple but beautiful single-flight staircase with decorative railings.

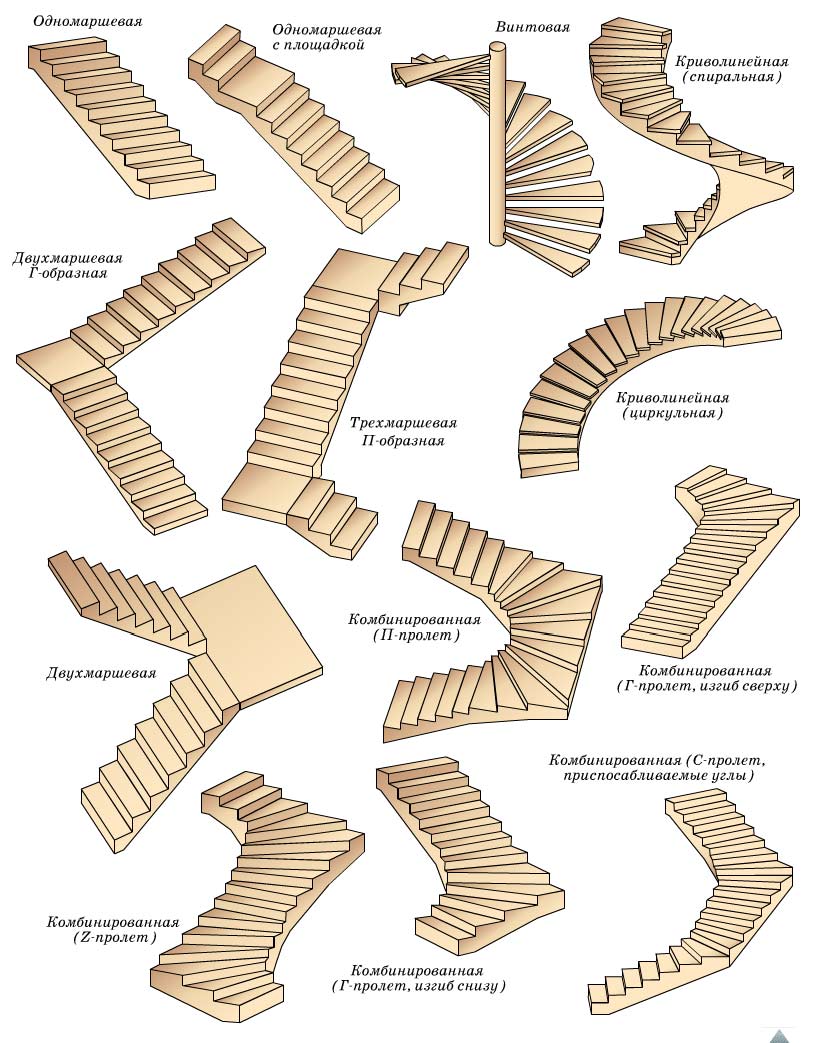

Types of stairs

All stairs connecting the first and second floors can be divided into:

- Type of spans:

- single-march;

- multi-march.

- Shape:

- straight;

- screw;

- corner;

- curly.

- Material:

- wooden;

- metal;

- combined.

Choosing the type of staircase

The choice of staircase type is influenced by many factors, such as floor height, ability to create complex designs from various materials, the presence of free space around the future staircase and many others. If you decide to make a ladder yourself, then first of all you should evaluate your skills as a carpenter and welder; this will help you choose the material from which the ladder will be made. If you are a good welder, you can make a ladder of any complexity from metal and any other materials. If you are a good carpenter, you can build wooden stairs of any complexity. Not all people have such talents, so don’t despair if you don’t really know how to cook or carpenter, this won’t stop you from creating a simple, but beautiful and reliable staircase connecting the first and second floors.

Having decided on the material from which you will build the staircase, proceed to choosing its design. Below we provide a list of basic requirements that must be taken into account when choosing the type and size of a staircase; this will allow not only to build it, but also to make the staircase comfortable and safe:

- staircase angle 30–45 degrees;

- if there is a cover above the stairs, then the distance from any step to it should be the same and be 2–2.2 meters; if there is no cover, then the distance to any obstacle at any point should not be less than 2 meters;

- the railings must be rigidly fixed and their height is 80–100 cm;

- optimal width stairs 1 meter;

- optimal step depth 30 cm;

- optimal height steps 15 cm;

- There must be sufficient free space in front of the lower and upper steps of the stairs (at least 2 m²).

One of the main parameters that influences the choice of the type of staircase is its elevation angle, which is 30–45 degrees (optimally 40 degrees). At an angle of 45 degrees, the length of the space occupied by the stairs will be equal to the height of the floor plus 1–2 meters. Extra distance It is necessary to make the stairs convenient to use, because you will have to not only walk on them, but also carry furniture. If there is such free space - optimal choice- single-flight staircase. Its advantage is its small width - with a step width of 1 meter, the width of the stairs is outside the railing does not exceed 120 cm. If there is no free space of this length, you will have to build a multi-flight, spiral or corner staircase, which are much more difficult to manufacture. In addition, the width of free space for spiral or multi-flight staircases is approximately 2.5 times the width of the steps, and the length of each flight with spans reaches the height of the floor. The width of the spiral staircase is 2.5–3.5 meters, this is due to the need to use wider steps, and it is also the most complex and expensive to manufacture.

Construction of a wooden single-flight staircase

Below we will describe the construction of a staircase with a step width of 1 meter, an elevation angle of 45 degrees and a height from the floor of the first floor to the floor of the second floor of 3 meters. This staircase provides a comfortable and safe climb to the second floor, looks very beautiful and is relatively easy to manufacture. It can be installed either in brick or stone, or in wooden house With wooden floors first and second floors. You can purchase all the materials for its manufacture at the nearest construction or hardware store, and there you can also buy all necessary tool.

Tools and materials

For work you will need the following materials:

- planed board 50x250 mm (two pieces of 5 meters each);

- block 50x50 mm (12–15 meters);

- bolts 11–13 cm long, 5–8 mm in diameter, nuts and 2 washers for each (108 pieces of bolts and nuts, 216 washers);

- planed board 35x150 mm (40 meters);

- planed board 35x115 mm (22 meters);

- turned balusters 100–110 cm high and 50 mm in diameter (26–32 pcs);

- support pillars with a cross-section of 10x10 cm and a length of 100–110 cm; you can use balusters of appropriate size (4 pcs);

- straight embossed railings 50–80 mm wide (15 meters);

- steel corners with shelves 10 cm long (12 pcs);

- anchor bolts, nails and screws of various sizes;

- wood putty;

- parquet varnish;

- acetone or solvent;

- wood glue.

You will also need the following tools:

- jigsaw;

- sander;

- screwdriver with a cross-shaped bit;

- wood hacksaw;

- drill with perforation mode and a set of drills;

- feather drill with a diameter of 20mm;

- hand cutter or milling machine;

- set of chisels;

- wrenches corresponding to bolts and nuts;

- square;

- protractor;

- pencil;

- roulette,

- hammer and mallet;

- sandpaper;

- brush;

- rubber gloves, respirator and safety glasses.

Manufacturing and installation of stairs

When planning to install a staircase, make sure that the floors of the first and second floors do not require repairs, because otherwise they may not withstand the load and collapse, causing not only the staircase to fall, but also the person on it. Then measure exact distance between the floor of the first floor and the floor of the second floor, then use the Pythagorean theorem to find the length of the stringer (bearing board) of the stairs. With a height of exactly 300 cm, the length of the stringer is 424 cm. If you are not satisfied with the angle of 45 degrees, then carry out the calculations yourself; school knowledge is enough for this. After all, the staircase forms right triangle, where the vertical leg is the height, the horizontal leg is the space occupied by the stairs, and the hypotenuse is the length of the stringer.

After this, calculate the number of steps.

Remember, if there are more than 18 steps, it is advisable to use a different staircase design, because a stringer without supports will not be able to provide the required rigidity.

Having decided on the calculations, mark the stringer boards, the angles of which should correspond to the angle of installation of the stairs, taking into account the total length of these parts. Make no mistake, because if you make a mistake, you will have to either increase the angle of the stairs or buy new stringer boards. Having marked and double-checked everything, cut the ends of the boards and apply them to the installation site of the future staircase to make sure that you have not mixed up anything. Both boards must be at the required angle and adjacent to the surface of the floor of the first floor and the end of the floor of the second floor without gaps.

Remove the stringer boards and start marking the steps. We offer the simplest method of attaching steps, which does not reduce the strength of the stringer and does not require special carpentry skills, just enough attention, caution and diligence. Steps made from two 35x150 mm boards will be supported by 50x50 mm bars attached to the stringer, and in front of the steps will be covered by risers - vertical boards measuring 35x115 mm. The steps will be attached using self-tapping screws, and the risers using nails. If you don’t mind self-tapping screws 70–80 mm long, then the risers can be attached to the stringer with their help. As a result, the steps are 26.5 cm deep and 15 cm high, which ensures high comfort while going up or down stairs.

Before you start marking, imagine the structure of each stage, then sketch it. If you were able to imagine and sketch them, start marking them. Determine the length of the bars so that they do not interfere with the risers and do not protrude from the back side of the stringer. Then mark the position of the bars taking into account the height of the steps. Remember, the first step should start with a riser resting on the floor. Once you've finished marking, make a template for drilling holes in the stringer and the bars, or mark all the holes manually on both the stringer and the bars. Set aside all work on the stairs for 1-2 days, then double-check all markings; if there are no errors, drill holes for installing bolts in the stringers and bars. When all the holes are ready, drill holes for washers from the outer surface of the stringers so that the bolts do not stick out above the surface of the board. This will not only increase the safety of the staircase, because no one will be scratched by protruding bolts, but will also make it more beautiful.

Despite the fact that many carpenters assemble stairs of this design using nails, we recommend using bolts and nuts. Nails required size(120–150 mm), if handled improperly, the bars often split, which is why they have to be changed frequently. This especially often happens when bending nails from the side of the bars. If you hit nails from the side of the bars, bending them onto the stringer, then the latter will have to be sheathed with veneer or plywood, which increases the complexity and cost of the work, because unlike smooth round holes, bent nails are very difficult to putty. Having finished installing the bars, begin marking the boards of the steps and risers. The length of the riser and back board is 100 mm, the length of the front board is 110 mm. This is necessary so that the steps look embedded into the stringer, because such a design looks more beautiful and reliable. All boards must be cut at a 90 degree angle.

Having finished cutting, milling machine or use a hand router to cut the top front edge of the front board to give it a rounded or shaped shape, since a step with a clearly defined top front corner looks unsightly. If you cannot do this work yourself, contact the nearest carpentry workshop or furniture workshop; for a small fee they will handle everything quickly and easily necessary boards. After this, mark and cut the outer boards so that they evenly protrude above the stringer. The next stage of work will be the installation of balusters and railings on the stringer; for this, round tenons with a diameter of 20 mm and a depth of 3–5 cm are cut at the ends of the balusters, and in the stringer and bottom side the railings are drilled with corresponding holes. All holes and tenons must be made taking into account the angle of inclination of the stringer. When everything is ready, the stringer, balusters and railings are assembled into one structure, first dry, then, if everything is fine, they are assembled with glue. Next stage– installation of stringers and adjacent end balusters. For fastening to joists and floor surfaces use metal corners and powerful screws. Then risers and steps are installed and secured. When the entire staircase is ready, the horizontal parts of the railing are installed, then the entire structure is sanded, cleaned of dust and varnished in several layers.

Some people don't want to build cottage and they are building a multi-story building, and it will be impossible to move around the house without stairs. There are stairs different forms and made from different materials. The stairs that are located between floors are made of metal and.

The design and calculations for stairs located between floors made of any materials are no different.

The design and calculations for stairs located between floors made of any materials are no different.

They have the usual requirements:

- In a private house, the smallest staircase width is 900 centimeters.

- The normal height of steps is 160 - 180 millimeters.

- The minimum permissible depth of steps is 270 millimeters.

- The railings on the stairs must withstand about one hundred kilograms of lateral pressure.

- The distance between the railing posts should be 150 millimeters and, if there are children in the family, this distance should be 120 millimeters.

- Stairs are made forged and welded.

There are the following types:

There are stairs:

If you do not have special skills in building stairs, then start with simple option, that is, with a single-flight design.

Necessary calculations

Organizations that develop projects use special ones to design 3D models of structures using these programs. In the model, it is very easy to change the parameters of different parts.

Organizations that develop projects use special ones to design 3D models of structures using these programs. In the model, it is very easy to change the parameters of different parts.

After approval of the final version, the computer program prepares specifications and drawings of the metal staircase.

But in our case, the calculations will have to be done without the help of a computer program. We will consider a simple version of a direct single-flight design.

But in our case, the calculations will have to be done without the help of a computer program. We will consider a simple version of a direct single-flight design.

The basic requirements for the depth and height of steps are already known. It is necessary to take measurements between points, that is, from the beginning to the end of the stairs from the floor of the first floor and the height between the floors of the first and second floors. Now we determine the length of the stairs; we must remember that the average angle of inclination is from thirty to forty-five degrees.

We calculate the available parameters and extract Square root and get the length of the stairs.

Materials and tools required for work

To build an interfloor metal staircase, we need to build an interfloor metal staircase You will need the following tools and materials.

Tools:

Materials:

Carrying out work

Stages of work:

First of all, angles for attaching steps, that is, fillets, are made from corners.

You cannot make a mistake so that there are no various distortions and flaws that will spoil the stairs.

Also, the fillies must be identical and must be exactly opposite each other. The fillies are made from a corner by cutting out a sample and joining the corners together.

Also, the fillies must be identical and must be exactly opposite each other. The fillies are made from a corner by cutting out a sample and joining the corners together.

The result is L-shaped nodes with the shelves down and inward. For our design, fourteen pairs of these nodes are needed, and in each pair, one support will be left and the second will be right. Then we weld the brackets to connect the steps and the horizontal crossbar between each pair of corners.

We also make the horizontal crossbar from a corner. The structure is strengthened with the help of gussets; we weld them from the bottom of the step towards each of the stringers.

We also make the horizontal crossbar from a corner. The structure is strengthened with the help of gussets; we weld them from the bottom of the step towards each of the stringers.

Along the edge square pipe We make markings from the profile and, according to the markings, weld the fillets to the edge of the stringer, attach the second stringer to the first stringer with fillets and transfer the markings.

We make and then weld the stringers with the lower end to the support platform. If in houses concrete foundation, then the support platform is installed in concrete. We attach the upper end to the support post; the support post is secured to the ceiling between the floors with steel anchors. Then the fillies need to be checked for level again.

We make and then weld the stringers with the lower end to the support platform. If in houses concrete foundation, then the support platform is installed in concrete. We attach the upper end to the support post; the support post is secured to the ceiling between the floors with steel anchors. Then the fillies need to be checked for level again.

If the staircase is made near a wall, then to add rigidity to the structure, one stringer is welded to brackets that are fixed to the wall.

They involve welding the steps to the fillets, you can also secure them with bolts, but in this case you need to cover the steps with wood. The steps can also be installed on wooden steps using screw connections.

It seems that constructing an interfloor staircase structure is not such a difficult task, but this work requires precision, accuracy and care.

In the article we told you how to make a metal staircase to the second floor.

In the article we told you how to make a metal staircase to the second floor.

One of the serious stages interior design two-story private house - construction of a flight of stairs intended for climbing upstairs. Here the homeowner is faced with a choice: hire for this work experienced craftsmen or start making it yourself. The second option is supported by cost savings and the conscientiousness with which the owner will get down to business in his own home. All that remains is to fill the gap in knowledge and understand how to make a staircase to the second floor with your own hands, having carefully studied our recommendations.

Staircase diagrams for climbing to the second floor

To build an interfloor passage yourself, you need to choose a suitable structure that will fit in the allocated area and at the same time be safe to use. But first you should understand the names of the elements and details of the stairs:

- bowstring (otherwise - stringer) - a longitudinal beam that serves as a support for the steps;

- tread – the upper plane of the step;

- riser - an opening between two treads;

- the support post is used in some structures for the installation of stringers or steps;

- baluster - vertical support for railings.

Straight staircase 1 flight

To organize the ascent to the top floor of a private house, it is customary to build 4 types of stairs:

- Straight marching with or without a transition platform.

- Rotatable 90 or 180° with winder steps.

- Screw.

- Compact goose step ladder.

Reference. For the sake of saving usable area And building materials the listed structures are located along the walls. The exception is a screw structure located in any convenient location, even in the middle of the hallway or hall.

A simple staircase to the second floor consists of one flight with a railing. It is not difficult to make, but with a ceiling height of more than 2.5 m, the building will take up a significant area. To save space, it would be more correct to make the ascent according to a scheme with two flights and a transition platform, as shown above in the photo.

The design of turning (winder) steps allows you to effectively use the entire length of the staircase and thus reduce the size of the span. The assembly of such a structure is somewhat more complicated due to the installation of a support pillar and the manufacture of wedge-shaped shaped steps.

Drawing of a turning staircase

If there is very little space in the house or country house, then it makes sense to build a spiral staircase or a “goose step” type structure shown in the photo. In the first case, all the steps are winders and are attached at one end to the support pillar, and in the second they are cut in width so that you can put your foot on only one side. It is quite difficult to make a screw structure from scratch, but the goose step ladder is built using the same technology as conventional marching ascents.

Note. Typically, homeowners purchase metal, wood, and glass spiral staircases as ready-made kits that are installed on site. It's easy to find on sale now beautiful products, in harmony with any interior, but such pleasure cannot be called cheap.

This is what a steep flight of stairs looks like, like a goose step.

To finally select a suitable staircase design for the second floor, you should calculate the size and number of steps.

Calculation of interfloor stairs

For calculations, you need to know the height difference between the finished floors of the first and second floors, as well as the size of the area that you are ready to allocate for a conditional staircase. The calculation method does not depend on the chosen design and is based on the following requirements to ensure convenience and safety during its operation:

- tread width - at least 26 cm;

- step height – no more than 20 cm;

- the slope of the flight of stairs should be within the range from 27 to 42°;

- railing height – from 900 mm;

- The minimum span width is 90 cm.

Advice. In order to correctly calculate the parameters of a flight of stairs and decide on its design, it is recommended to solve the problem graphically. Make your own mini-project by drawing by hand or on the computer drawings showing the staircase in plan and side view.

The essence of the calculation is to determine the number of steps and the total length of the climb, taking into account the slope of the homemade ladder. It is proposed to consider the order of calculations using the example country cottage with a height difference of 3 m:

- To prevent the climb from being steep, let’s take the most convenient riser height – 15 cm. The number of steps is calculated by dividing the total height by this value: 300 cm / 15 cm = 20 pcs.

- Taking the width of the tread equal to 30 cm, we calculate the length of the span: 30 cm x 20 = 600 cm or 6 m.

- Having drawn a sketch of such a wooden staircase with a side view, we will determine the slope angle - 27°.

Design diagram of a straight march with a slight slope

The 6 m long structure shown in the picture will not fit into every home, so its design will have to be adjusted. Option one: break the climb into 2 flights of equal length and make a transition platform. Taking into account its size, which is equal to the minimum span width, the length of the ladder will be 3.9 m, which is also quite a lot. To some extent, sacrificing amenities, the dimensions of the stairs can be optimized as follows:

- reduce the width of the step to 26 cm;

- increase height to 18 cm;

- move the tread forward 3 cm.

Optimized staircase diagram

Using the instructions given above, we calculate the new parameters of the flight of stairs and get the number of steps 17 pcs., the angle of inclination is 37°, and the total length is 3.7 m. If we organize a 90° turn of the flight with three winder steps instead of a landing, then the length of the rise it will be possible to reduce it to 3 m, and this is quite acceptable. More visual information about the calculation flights of stairs you will receive by watching the video:

Important point. All home buildings, including interfloor stairs, must be safe for small children. Provide gaps between the balusters according to the child’s age so that he cannot squeeze between them and fall.

Construction materials

The best material for making a staircase with your own hands is wood. It is not only easy to process, but also fits well into any interior. Metal structures more durable, but at the same time heavier and more difficult to assemble, not to mention the cost of iron elements. Dried wood of the following species is suitable for construction:

- ash;

- aspen;

- coniferous species: spruce, pine, larch.

Advice. You should not use birch for construction inside a house, as it quickly dries out and loses its appearance.

To make stringers, you will need a board with a thickness of 40 mm or more of the required length (splicing a bowstring from pieces is unacceptable). The width of the board should be 25-30% greater than the calculated tread width. A wooden beam with a cross-section of 10 x 10 cm or more, depending on the length of the supporting part and the weight of the structure, is suitable for the outer and intermediate posts for the railing.

The appearance of a wooden staircase largely depends on the design of the balusters. In order to beautifully design the railing, it is better to order the production of balusters somewhere in production, where they will be turned according to your drawing lathe. If you are skilled in wood carving, then you can design the stands yourself. Also, do not forget to purchase fasteners - self-tapping screws, metal pins or dowels for installing balusters, nails.

Installation Guide

IN Lately wooden stairs to the second floor, equipped with turning steps, have gained popularity. They take up little room space and are relatively easy to assemble, so we will give step-by-step instructions for installing such a structure. First of all, prepare the necessary tools and a stepladder or a simple ladder for temporary access to the second floor. Then proceed in this order:

- Mark the blanks according to your drawing. For convenience, you can make a wooden template to draw cutting lines along the stringers using one sample. Cut out the pieces with an electric jigsaw.

- Install the support post and attach it as shown in the picture below. Make grooves in it for attaching winder steps and bowstrings.

- Secure both stringers - screw the first one to the wall, and the second one to the vertical post and the end of the interfloor ceiling.

- To support the winder steps, install horizontal bars on the wall. Mount 2 strings for a short flight - the entrance to the stairs.

- Install all the steps, moving from bottom to top. Mark the attachment points for the balusters on them.

- Secure the balusters to dowels or studs, and install the railings.

Scheme of fastening the central support and assembling the flight of stairs

Advice. Do not cut 3 turning steps from one block. It turns out that the fibers of the first of them will be located across the length of the tread, causing the step to break at the slightest load.

Risers homemade stairs it makes sense to make them closed if you plan to sew up the space under the march (for example, for a pantry). In other cases, it is not necessary to seal the openings between the steps. To extend the service life, finish the flight of stairs - treat the wood antiseptic composition and varnish. How to properly assemble a turning ladder yourself is described in the next video:

Conclusion

When building a wooden staircase, pay special attention to the preliminary stages - calculation, marking and cutting out parts. If you make a mistake here, it can be difficult to eliminate it during assembly, including redoing the stringers. Think about the design of balusters and railings, study existing options from photographs and choose the most interesting and suitable for the interior of your home.

Design engineer with more than 8 years of experience in construction.

Graduated from Eastern Ukrainian National University them. Vladimir Dal with a degree in Electronics Industry Equipment in 2011.

Related posts:

Ladder- this is one of the main elements of the interior design of a room, therefore, when designing it, attention should be paid not only to reliability and functionality, but also appearance. Before you take on making a wooden staircase with your own hands, need to be taken into account a large number of factors on which not only its design, but also its dimensions will depend.

These factors include:

- available room area,

- height,

- the maximum load for which the ladder is designed,

- ease of use for people living in the house.

Today there are a huge number of design options interfloor stairs, so the choice suitable design- the task is quite difficult..

Choosing which staircase to build

Marching and spiral staircases. The design of the flight of stairs is quite simple and is best choice, if you plan to make it yourself, however, in order to ensure an acceptable slope and height of the steps, a considerable area is required. This ladder is very easy to use and can withstand heavy loads. It can be used to easily lift furniture and other large objects to the second floor; in addition, it is safer, so it will be the best choice if children or elderly people live in the house.

The spiral staircase has a more complex structure. It is used in conditions of limited space, when due to lack of space it is not possible to provide a safe slope of an ordinary staircase. The main disadvantages include the not very convenient design, which makes it difficult to lift and does not allow carrying large objects. At the same time, a skillfully made spiral staircase has sufficient strength and can be the main element of the interior.

Safety first!

Before you start DIY staircase making, you need to take care of her safety. Firstly, it must be durable and easily withstand a load several times greater than the weight of a person of average build. Secondly, the ladder should be comfortable and ergonomic. In this case, it is necessary to pay great attention to such factors as the height of the steps, the slope of the stairs, as well as the location and shape of the railings. The steps must have a non-slip coating, and the spaces between the balusters are chosen in such a way that the child cannot squeeze through them and fall.

Design features of stairs

Depending on the method of fastening the steps, flight stairs can be on bowstrings, stringers or rails.

- Stairs on bowstrings have two side beams to which the steps are attached. Such squirrels (strings) can be made of metal or wood. They can be attached to a wall or special supports, ensuring high strength of the entire structure.

- The steps of the stairs on stringers are attached to beams, which are located below and repeat the geometry of the entire structure. Such beams (stringers) can be straight or curved. Straight stringers, as a rule, have a jagged shape, with the steps superimposed on the teeth.

- Stairs with bolt-jointed steps are highly durable, so this design does not require additional supports and can be held on two points. The steps are attached to each other using metal rods- bolts, which completely eliminates creaking caused by friction of two wooden surfaces.

How to make a staircase with your own hands. Selecting materials

Wood is most often used to make stairs coniferous species, because it is affordable and easy to process. An oak staircase will be more durable, but the cost of such a structure will increase several times, and besides, processing this type of wood is quite labor-intensive and requires certain skills.

The main stages of staircase manufacturing

Let's look at the basic principles of making stairs using an example wooden structure on stringers. Before you start designing, you need to understand that any, even minor errors and inaccuracies in calculations can lead to serious problems that arise during installation, so each stage should be treated with extreme care. Our future staircase will consist of three main elements: steps, handrails and stringers. On initial stage design, you need to perform all the necessary structural calculations.

Calculation of the width and height of steps

To calculate the size of steps, the formula 2A + B = 64 cm is usually used, where A is the width and B is the height. Typical step heights range from 140 to 170mm. We measure the height of the future staircase and divide by the expected value of the height of the steps.

Let's assume it is 240cm, and the desired height of the steps is 17cm. We divide the resulting value by the height of the steps 240/16=15 and round the result to the whole part, therefore, our future staircase will consist of 15 steps. Now we define exact height steps, to do this we divide the height of the entire staircase by the number of steps: 240/15 = 16 cm. We find the width using the formula, using the height value, we get 24cm. You can also use the table.

The protrusion (the part of the step overhanging the riser) should be no more than 3-4 cm. How more height the riser, the narrower the step itself, however its width should not be less than the height. The most optimal width of the steps should correspond to shoe size forty-two (29-30 cm.)

When calculating the stairs, it is also necessary to take into account the distance between the steps and the objects located above them (ceiling, beams, balconies, etc.). It should be at least 1.9-2 meters.

The horizontal size of the stairs is determined as follows: the width of the steps is multiplied by their number, it should be taken into account that the floor surface serves as the first step, so in our case the calculation will look like this: 13x24=312cm.

If the height of the stairs is large enough, you can make a platform. It is recommended to make such platforms in 7-8 steps. In the case when it is necessary to design a staircase with a certain number of steps, you can reduce their height in order to create a landing.

Making stringers

As a material for making stringers, you can use a 40mm wide pine board. Make a pattern that exactly repeats the dimensions of the steps' profile and apply markings to the prepared boards. Then cut out the teeth using a hacksaw or electric jigsaw. In those places where the riser meets the step, it is necessary to cut the corner. Having made one stringer, you can use it as a template for the rest. Since the strength, safety and durability of the staircase depend on the stringers, you should not skimp on their quantity, as well as on the quality of the material from which they are made. The boards must be free of knots and any signs of insect activity. Consider how to attach the stringers. For achievement required strength As a rule, 3-4 stringers are enough.

Installation of steps and railings making wooden stairs with your own hands

The steps can be attached either directly to the stringers or with the help of additional wooden elements - fillies. Measure and cut from wood required amount steps and risers, be sure to take into account the overhang. The steps are attached using nails or self-tapping screws.

The design using triangular fillies is more reliable. The fillies are attached using dowels, for which grooves are pre-made. The most durable design is obtained using fillies complex shape, while a special cutout is made on the stringers. The connection of the staircase elements is carried out using glue and self-tapping screws.

After the steps are ready, you can screw the railing balusters to them. In order to protect the tree from the influence of destructive factors (dampness, mold harmful insects), it must be coated with paint.

Making a wooden staircase with your own hands is, in principle, not so difficult. All you need for this is quality wood, the necessary tools and a little patience. Before you start work, carefully consider all the nuances future design and check your preliminary calculations several times.

Today, the construction of a private house is not limited to one floor, so it is necessary to build a staircase to the second floor in order to be able to get easy access. It is quite possible to build a staircase from various materials yourself, the most important thing is to carefully carry out all the required calculations, since otherwise this design can become dangerous and unreliable.

Construction of an internal staircase in a private country house– the process is quite complicated, but quite doable.

When constructing a staircase you must:

- Consider the interior of the house;

- Make all required calculations;

- Choose a design that will suit all parameters.

To easily select the most appropriate option, you should first schematically draw the staircase that should be in the house or already found ready-made option, which is most suitable for all requests and can already be adapted to your needs. Before choosing a staircase model for a private home, it is important to correctly calculate all the available design parameters. Many people wonder what better stairs do.

Most often, stairs in a residential building are made from materials such as:

- Tree;

- Concrete;

- Metal.

According to its configuration, the staircase can be straight, spiral or rotary. In addition, there are also combined options. Concrete products are considered the most durable and durable, however, they require quite a lot of preparation time solid foundation and fabrication of the structure. Metal structure can be made quite simply, you just need to know the rules of working with welding, and a wooden staircase can be made very easily yourself, the most important thing is to read the step-by-step instructions for its manufacture.

The easiest way is to make a straight flight of stairs, since it has a small number of parts and takes up absolutely little space. Screw designs are characterized by the fact that they require a small area; they look very elegant, however, they are not always convenient to use.

A staircase of several flights is considered a rather complex structure, which is problematic to build. This design is ideal for a home where there is a significant distance between floors.

Instructions for making a simple wooden staircase

The simplest design is considered to be a simple one-flight staircase.

It consists of:

- Kosourov;

- Railing;

- Tread;

- Riser.

To calculate the height, you need to take the distance between floors and add the thickness of the floors. In order to quickly calculate what the length of the span and base should be, you should initially decide on the parameters of the steps. If small children live in the house, the optimal height of the steps will be 15 centimeters, and in all other cases it should be equal to 20 centimeters. It is not worth making the risers higher, as the rise will be less comfortable.

The optimal width of the steps should be 20-30 centimeters, since if they are wider, the entire structure will take up much more space, which may not be entirely convenient.

Exists step-by-step instruction manufacturing a staircase, which must be adhered to, as this will allow for fairly high-quality and robust construction. To make a staircase, it is necessary to select durable and strong wood, since all elements of the staircase must withstand not only total weight structures, but also people. It is necessary to cut out a template from durable cardboard that will correspond to all the parameters of the future staircase, and then make it using this template wooden elements for the stairs. Then you need to collect all the elements of the staircase and treat them with antiseptic solutions, coat them with paint or varnish.

How to make a staircase quickly and easily from concrete

If the house has concrete floors second floor, then you can arrange a concrete simple stairs, which will be durable, and with correct processing will look very beautiful. You can make a completely concrete staircase in the house, or fill only the stringer with concrete, and make everything else from other materials.

To produce such a staircase you will need:

- Waterproof plywood;

- Durable timber;

- Fittings;

- Self-tapping screws;

- Concrete solution.

Construction concrete stairs requires special attention, so everything must be carefully calculated, since the base must be very strong. You need to start by assembling the formwork, which must be done according to all available drawings and taking into account the fact that there should be absolutely no gaps.

The finished formwork must be placed between floors and secured with wooden beams. After this, it is necessary to lay reinforcement inside the frame and fill the prepared base with concrete mortar.

It is necessary to fill the frame with mortar immediately, otherwise the solidity of the finished structure may be damaged. When the concrete has hardened well enough, the formwork can be removed and the steps can be periodically watered with water to avoid cracking of the concrete. The structure must dry thoroughly and then you can begin finishing the stairs. You can design the finished design in the most various materials, in particular, you can use wood, stone, tiles and many other materials.

Quick and easy: building a staircase in a private country house made of metal

Homemade ones look quite interesting and original, however, to make them you need to put in a little effort and take into account all the features of working with this material. To install a metal staircase, you must first prepare some materials and tools.

In particular:

- Steel channel;

- Metal corners;

- Welding machine;

- Sheet metal;

- File.

Forged stairs have excellent aesthetic and performance properties. Read more about forged stairs in the material on our website:.

To build a staircase, you must begin by cutting the channel into pieces and assembling the frame from them. Weld corners to the side edges of the frame at equal intervals, which will be equal to the height of the steps. All corners must be located strictly parallel to one another. The upper ends of the frame are firmly fixed and attached to the ceiling of the upper floor, and the lower ends are secured to the floor. Then the steps are welded sheet iron, as well as railings. At the final stage finished design treated with special anti-corrosion mixtures. In order not to redo the structure, it is necessary to carry out all stages sequentially and strictly follow all the rules of its construction.

Tips on how to make your own staircase in a private country house: screw-type construction

The spiral staircase, which takes up quite a bit of space, looks quite interesting and original. free space. This compact design, which can be placed even in a small area. The spiral staircase can go from the first floor or from the garage, which is very convenient. The most famous and widespread method of installing spiral staircases is step-by-step stringing of steps onto a central base. The steps can be triangular or trapezoidal.

To build spiral staircase you need to take:

- Steel pipe;

- Wooden slats;

- Welding machine;

- Corners for steps;

- File;

- Primer.

The pipe will act as a central post, so its length must fully correspond to the existing distance between floors. For greater stability, it is necessary to concrete the pipe near the base. To make steps it is necessary to use templates made from wooden slats. They must be glued together in such a way that they form steps with the given parameters. Each step must be attached to its own pre-prepared cylinder, carefully sanded, primed and painted.

If necessary and for greater convenience, the spiral staircase can be converted to a straight structure. Before installing a permanent staircase, a temporary structure is installed.

What types of construction can there be?

If you have firmly decided to build a staircase in a private country house, you should initially determine what kind of design it should be.

In particular, it is quite possible to distinguish such types of structures as:

- On stringers;

- On pain;

- Screw.

The most popular are staircases with stringers, as they are suitable for rooms of different sizes and stylistic solutions. This device is very durable and guarantees safety during its operation. Many people prefer to make a staircase on rails, the peculiarity of which is that all structural elements are fastened together using special bolts and pins. If necessary, you can very easily repair it and completely disassemble it.

DIY staircase to the second floor (video)

It is quite possible to make a staircase in a private country house yourself, the most important thing is to strictly follow all the rules and requirements.

Details: do-it-yourself staircase to the second floor (photo examples)