An attachment for an electric drill for chopping grapes. Grape crusher: rules for selection and self-production

DIY grape crusher, design drawings with one drive roller, with the ability to adjust the gap between the rollers.

This mechanism is designed for chopping bunches of grapes and separating the ridges.

Before starting design, it is necessary to carry out a simple technological calculation.

1. Calculate the productivity of the roller crusher (kg/s) using the formula:

П = ½LDδωρφ

L – roll length (m), 0.215

D – roll diameter (m), 0.1126

δ – gap between rollers (m), 0.006

ω – roll angular speed (rad/s), 6.28 (60 rpm)

ρ – density of grapes (kg/m3), 1364

φ – crusher utilization factor, 0.5

P = ½ x 0.215 x 0.1126 x 0.006 x 6.28 x 1364 x 0.5 ≈ 0.3 (kg/s)

2. Eight-blade profile roller.

The diameter of the blade is taken to be the maximum diameter of the berry 18 (mm).

3. Technical parameters of the destemmer:

Turn pitch length (mm), 200

Number of whips per step length (pcs), 8

Distance between whips (mm), 25

Number of turns, 3

Rotor speed (rpm), 120

4. We build a kinematic diagram of the crusher taking into account the obtained parameters.

5. Determine the power of the electric motor (kW) using the formula.

N = 0.119LDn(120d + D2)

L – roll length (m), 0.215

D – roll diameter (m), 0.1126

d – berry diameter (m), 0.018

n – roll rotation speed (rpm), 60

Substitute the values into the formula and get:

N=0.119 x 0.215 x 0.1126 x 60 x (120 x 0.018 + 0.215 x 0.215) ≈ 0.38 (kW)

[i]6. Let's start building the product.

The grape roller crusher consists of the following components:

- Frame.

- Bearing housing cover.

- Roll.

- Desalter.

- Sieve.

- Plexiglas.

- Electric motor AIR63V2.

- Ridge unloading bunker.

- Loading hopper.

- Gear.

- Belting.

General drawing.

Welded stainless steel construction. The main requirement is to maintain the alignment of the holes and grooves, their perpendicularity to the drilling and milling plane.

BEARING HOUSING COVER

It consists of a plate to which bearing housings are welded. When installing the cover on the body, the axes of all holes and grooves of the cover must coincide with the axes of the holes and grooves of the body and lie on the same line.

- Roll.

- Rubber compressor.

- Prismatic key 6x6x20.

- Prismatic key 6x6x70.

- External retaining ring 20x1.2.

COMBET SEPARATOR

Made of thin stainless steel sheet metal, in the form of a half-cylinder with staggered holes with a diameter of 16 (mm) along the entire length.

Plexiglass

Closes the comb separator from above and makes it possible to observe the process of comb separation.

ELECTRIC MOTOR AIR63V2

Since the working speed of the mechanism is small, it is necessary to use a frequency converter together with the selected electric motor.

GEAR

Gear parameters.

Many gardeners grow grapes to make homemade wine. The berry processing operation includes: extracting juice and separating the pulp. You can crush and crush the berries manually (for small volumes) or in a press. More zealous gardeners use specialized crushers for these purposes. You can buy them factory-made or build them yourself. For self-production, it is necessary, at first, to study the types of structures and the basic functioning of the mechanism.

Varieties

All units are divided into mechanical (manual drive) and electrical (electric drive). Mechanical and electric presses may have completely different operating principles. The difference lies only in the absence or presence of an electric drive. Any type of grape crusher has a number of positive qualities and disadvantages. Winemakers choose a device taking into account the volume of processing and the required productivity.

With destemmer

A device equipped with a comb separator is a mechanism that not only crushes the berries, but also frees them from the stalks (ridges). This device has a simple structure. Grapes are placed in the tray, and an auxiliary roller is used to separate the berries and stalks. After this, the grapes are crushed using two crushing rollers placed on opposite edges. The pulp ends up in a special department. Mechanisms with a stalk separator are centrifugal-impact and roller.

Important. The use of a crusher with a manual destemmer is not practiced for Muscat table grape varieties. These grapes are harvested when the fruits are slightly withered and it is no longer possible to separate them from the stalks.

Without destemmer

In terms of their design, units equipped with a ridge separator and those without one do not have any significant differences, with the exception of the absence of ridges and the functionality of separating fruits from the cluster. The procedure for processing raw materials is implemented more slowly due to the fact that the grapes require advance preparation - separating the grapes from the scallops.

Mechanical

Mechanical presses are available for sale in two loading methods: horizontal and vertical. In most cases, this applies to centrifugal type devices. This type of crusher operates through a centrifugal (tangential) force, with the help of which the grapes hit the inside of the hopper with force. In this case, the fruits are not only perfectly crushed into small parts, but also saturated with oxygen.

Mechanisms of this type are used to make red wines. Because a satisfying yield of wine material with an increased amount of tanning and coloring compounds is obtained. This device, simultaneously with the fragmentation of the fruits, separates them from the stalks. The design of the unit includes: a housing equipped with a power-driven lid, a shaft with blades, a receiving hopper and a tray along which the ridges are removed.

Electrically driven

This design is equipped with two handles that activate the shafts and the ridge separator, squeezing out the juice. It is not difficult to modify the equipment by connecting both mechanisms into a complete manual or electrical control (installation of an electric drive).

Valkovaya

Crushers of this type are intended for separating grapes from the ridges with further crushing of the raw materials. The structure of the roller crusher includes: a punching shaft, a perforated (with holes placed in a certain order) cylinder and 4 rolls made of food-grade rubber, which function in pairs. The operating principle of the crusher is as follows:

- the berries enter a device where, under the influence of beating shafts, the scallops are separated from the grapes and removed from the perforated cylinder;

- then the grapes fall through the perforations onto the shafts, through which crushing is carried out.

The crusher is equipped with auxiliary devices that adjust the distance between the rolls within 3–8 millimeters. This allows, if necessary, to apply gentle pressure on the berries, depending on their quality characteristics and variety.

Manual

If the harvest is small, then any crusher can be replaced with a manual device. To do this, you need to purchase a whisk for construction mixers. The use of a whisk made on the basis of metal rods will productively and freely crush grape berries, but at the same time it will not grind the seeds.

To crush grapes in a similar way, pour a small amount of berries into a container and beat with a whisk. In 2-3 minutes the pulp will be ready. Another good thing about using this crushing method is that after crushing it, you can safely remove the separated scallops. The finished pulp is poured into another container and left to ferment.

How to make a crusher with your own hands

Today in stores there is a wide selection of devices for processing the resulting grape harvest, in particular, a mechanical crusher for grapes DV-3. However, if for some reason you are not suitable or not satisfied with the existing assortment, you can take on making such a device yourself. A grape crusher is a simple device from a technical point of view.

Creating such a unit will not take much time and will not require significant financial investments. At the same time, the performance of a homemade crushing device is not a bit worse than the factory equipment.

The stages of creating the simplest design are as follows.

- Make a drawing of the device or use a ready-made one as a basis.

- Install a receiving hopper for filling raw materials. The configuration of the bunker is similar to an inverted truncated pyramid. The optimal material for its creation is hardwood (for example, oak). It is also possible to use stainless steel and plastic.

- A blade shaft (from 4 to 6 blades) is mounted along the lower section of the receiving hopper. To create it, you need to take a tube (30-40 millimeters in diameter) and stainless steel plates (15-20 centimeters in length, 8-10 centimeters in width). The plates must be welded to the tube in a checkerboard pattern (alternating the sides of the mating elements every now and then).

- We insert the blade shaft into the holes located in the lower segment of the receiving hopper.

- We fix the net in the lower section of the receiving hopper. Its diameter should correspond to the size of the grapes being processed. You can prepare at once a certain number of elements from steel mesh with different cell sizes and replace them taking into account the type of grapes used.

- The shaft is driven by a handle. To do this, you need to bend the rod (at least 10-12 millimeters thick), giving it the shape of a broken line. One edge of the handle is fixed to the shaft.

- The basis of the device is the frame. It must be put together from wooden parts in dimensions that slightly overlap the dimensions of the lower section of the bunker. It should be at least 15 centimeters in height.

- 2 shafts are attached to the frame with a distance between them of 2-3 millimeters. In order for the shafts to rotate towards each other, pulling the fruit inward, 2 gears are required. They can be taken from any mechanical device or ordered from a workshop that carries out turning work. It is especially important that the parts are of the same type. Gears are mounted on shafts from the outside of the frame.

- It is worth placing a handle on one of the shafts.

As a result, the most simple crushing device for processing grapes is ready for use. Whether to buy a factory crusher for grapes or make a simple device with your own hands is up to everyone to decide at their own discretion.

In any case, this simple technique will facilitate and speed up the procedure for preparing the initial wine product.

To learn about the types and rules for using a grape crusher, see the following video.

There are many nuances in home winemaking, without which it is difficult to obtain a good quality drink. In addition, the process of making wine is quite labor-intensive. Experienced winemakers, who process a large amount of harvest per season, make various devices to make their own work easier. From this article we will learn how to make a grape crusher with your own hands.

Purpose and principle of operation

Grape crusher- a device with a simple mechanism designed for processing berries. The design consists of a loading hopper, a container for collecting cake and two parallel crushing rollers. Grape crushers are used both in wine production on an industrial scale and in home winemaking.

The grapes intended for processing are poured into the loading hopper and crushed using crushing rollers driven by motion. The drive can be mechanical or electrical. Processed raw materials are discharged from a pulp collection container.

An important feature of a grape crusher is the presence of a gap between the crushing rollers. This allows you to leave grape seeds intact, which in a crushed state affect the taste of the finished product. The tannins contained in the seeds give bitterness to the wine.

Types of grape crushers

Types of grape crushers

Crushers are available with and without a destemmer. A grape crusher with a destemmer allows you to process raw materials much faster, because the berries do not need to be picked from the branches.

Shaft crushers- This is the most commonly used version of crushers both in production and at home. The operating principle is based on the opposite movement of two or more cylindrical shafts.

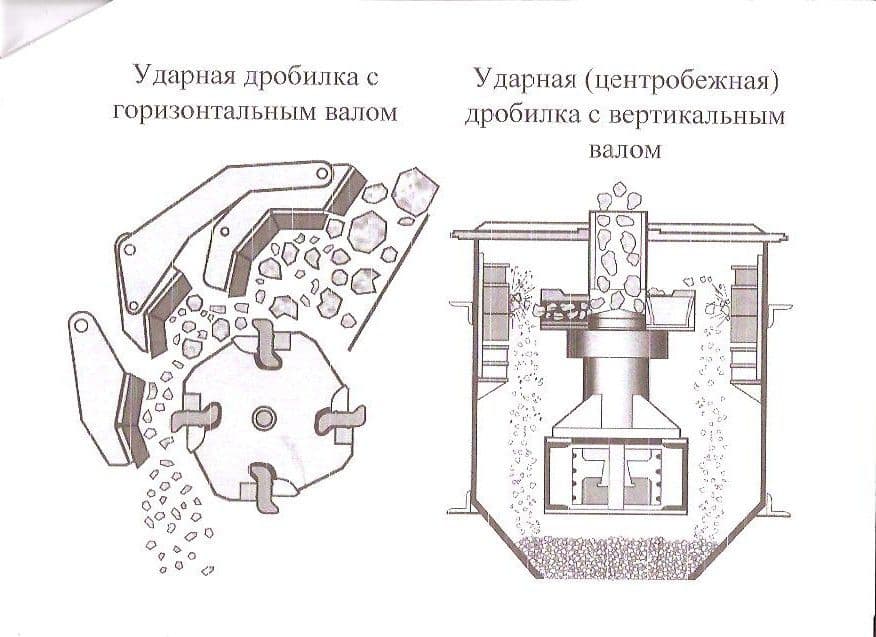

Impact centrifugal crushers can be horizontal or vertical. The operating principle is based on rotor rotation at speeds of up to 500 rpm. From its blows the grapes are crushed.

Mechanical and electric crushers can have exactly the same principle of operation. The only difference is the presence or absence of an electric drive.

How to make your own crusher

It makes no sense to purchase a factory crusher for grapes if you need to process your own harvest. You can make a fairly technologically advanced design yourself. Manufacturing the unit will not require much time and serious economic costs, and the efficiency of grape processing will not be much inferior to factory equipment.

You need to start by making a bunker. You can use any material for it, but it is preferable to take oak boards. If wood is not at hand, we use stainless steel or plastic. The shape of the bunker is an inverted truncated pyramid.

You need to start by making a bunker. You can use any material for it, but it is preferable to take oak boards. If wood is not at hand, we use stainless steel or plastic. The shape of the bunker is an inverted truncated pyramid.

Rollers can be taken from an old activator-type washing machine, which were used to spin clothes. On the rollers we draw 6 longitudinal lines around the entire circumference. Along the length of each line we drill holes at a distance of 0.5 cm. The diameter of the holes is approximately 10 mm, the depth is 0.5 cm.

In order for the rollers to rotate counter-rotating, pulling the berries inside, you will need 2 gears. They can be removed from any mechanism or ordered from a lathe. The main thing is that they are the same.

Now you need to make a wooden frame on which the rollers will be attached. For the frame you will need a beam with a section of 50x50 mm. The length of the frame should be equal to the length of the rollers. The rollers are fixed at a distance of 2-3 mm on the axis in the center of the frame. The gear system is installed from the outside.

Now you need to make a wooden frame on which the rollers will be attached. For the frame you will need a beam with a section of 50x50 mm. The length of the frame should be equal to the length of the rollers. The rollers are fixed at a distance of 2-3 mm on the axis in the center of the frame. The gear system is installed from the outside.

Now you need to assemble the structure. A frame with rollers is attached to a container for collecting pulp, and a hopper for receiving grapes is installed on it. The handle for driving the structure is mounted on one of the axes of the rollers. The simplest device for processing grapes with your own hands is ready for use.

Based on such a device, it is possible to manufacture a more advanced unit with an electric drive. We will need an engine, we can take it from the same unnecessary washing machine, a shaft and a transmission belt. Instead of a handle, an electric control with a belt drive is mounted.

To speed up the grape processing process, you can install a destemmer on the device. For the comb separator you will need a stainless steel mesh with cells of 10-12 mm and an additional shaft with blades. The blades are made of stainless steel in the form of small blades and are welded along the spiral of the shaft. The berries, entering the crusher using this shaft, are separated from the ridges and enter the roller system for further pressure. The ridges remaining on the mesh are dumped into an additional compartment.

Grape crusher- a device for obtaining pulp. The special design allows you to process large volumes of berries. When crushing, the seeds are not damaged, giving the juice a bitter taste. All types of crushers are divided into 2 main groups: mechanical and electrical. The choice of a specific type depends on the volume and type of berries being processed.

For a load of up to 700 kilograms per season, a manual model is sufficient. This is a simple form consisting of a frame, rollers and a container for the cake. Knowledge of the technical features of crushers and their main varieties will help you make the right choice. Advantages of the device, how to make a wooden model yourself.

Working principle of a grape crusher

Provides 3 technological operations at once:

- separation of juice from the cake through crushing the berries;

- thorough cleaning of twigs and seeds;

- if necessary, separating other parts of the plant.

Such a unit will be useful on a personal plot for the manufacture of... Regardless of the type, the unit consists of the following components:

- receiving hopper(the product is loaded into it);

- movable rollers of various shapes or a rotor(carry out the process of squeezing juice and producing grounds);

- container for collecting pulp and seeds. Read how to grow grapes from seeds.

The berries are crushed by rollers, the juice and cake end up in a container for the finished raw materials.

The mechanical type requires the greatest effort. It is rational to process the product by two people: one loads the berries into the hopper, the other turns the handle of the crushing mechanism. The option with a motor allows you to simply pour the product into the container and then pick up the pulp. Thorough cleaning improves the quality of the base.

A separate category includes destemming presses: roller or impact-centrifugal. They produce additional peeling from grape combs. These parts of the bunch are also needed because they add a hint of brightness and astringency to the finished wine. For the production of red wine varieties, such as Moldavian and Monarch, the use of pulp with ridges is allowed. Read about the Moldavian wine grape variety. When making white wines, such impurities are not allowed; you will need a type with a separator for enhanced purification.

Types of grape presses

For large quantities of raw materials, the most popular models are made from the following materials:

- stainless steel;

- plastic;

- varnished wood.

The DV-3 mechanical crusher is designed to obtain juice and pulp from grapes.

All components of the device that come into contact with the product must not oxidize. The most popular are mechanical (manual) and electrical devices made of stainless steel. Their components are convenient to disassemble and wash. They are durable and do not allow the appearance of foreign odors.

To process more than 500 - 700 kilograms of berries, it is recommended to use only a crusher with a motor.

With and without destemmer for berry processing

The operating principle of crushers with a destemmer is to use a shaft, through which the ridges are separated from the berries.

Roll crushers

The most widespread, used to obtain high-quality raw materials for wine wort. The basis of the unit is a system of horizontal cylinders or blades with adjustable clearance. Operating principle of the unit:

- consists of rollers, built-in destemmer;

- have only vertical loading type;

- horizontally located rollers rotate in different directions;

- there is an adjustable gap between the cylindrical choppers;

- it is activated by turning the handle (mechanical version) or using a motor.

The rollers in different models have different shapes: corrugated, bladed, smooth. Lobed species may have 4, 6 or 8 lobes. The ridges are separated by a special device and then pushed out. Cylinders with a smooth or grooved surface are more often used.

When in motion, the rollers rotate in different directions. Berries that fall between them are crushed. Their skin bursts and the juice and pulp are released.

Impact centrifugal devices

The centrifugal impact model uses a special rotor as its basis. Grinding and squeezing are carried out using the blows of a rotary mechanism. This technology helps to obtain the maximum amount of coloring substances. Design Features:

- vertical or horizontal loading type;

- electric type only;

- maximum yield of phenolic and coloring components;

- rotor rotation at a speed of 500 rpm.

Sectional diagram of an impact crusher.

At the same time, the ridges are separated and thrown out. The result is maximum wort yield.

Mechanical cars

The manual type of devices refers to the roller type of action. Wooden presses are often used to produce homemade wine. Large farms use stainless steel equipment to produce wort. The dimensions and weight of different models depend on the materials and components used. For example, crushers with de-stemming weigh more. The simplest unit consists of the following components:

- square bin;

- two smooth rollers;

- lower frame made of wood;

- gear system;

- side handle.

The vertical loading method is used. Such a device weighs up to 18 kilograms and is placed on a table.

Electric fruit and wine crusher

Allows you to fully automate the production of wort. Electric crushers include an additional ridge separator. The basis is made up of rotating helical-shaped metal blades or a rotor. They ensure the separation of the grapes from the ridges. They are pushed out with a forward movement, leaving only juice and extraction in the hopper for further wine production.

Most Grifo crushers are equipped with ridge separators. Considering the complete automation of the process, it is possible to significantly reduce the time and effort spent on processing.

Performance of different models:

- 1200 – 1500 kilograms per hour;

- up to 2000 kilograms per hour;

- 2000 – 2300 kilograms per hour.

Advantages of using the device

Advantages of producing pulp with an automatic crusher:

- fast processing of large volumes of grapes;

- rational use of resources;

- the opportunity to obtain high-quality pulp;

- automatic cleaning of cake, juice from twigs, excess ridges;

- simplicity and convenience of the unit, which can be improved if necessary;

The simplest wooden model can be assembled with your own hands. It will become a handy tool for owners of small vineyards.

Devices made of wood and stainless steel are popular. They are not subject to oxidation and corrosion. This ensures long-lasting use as the juice is highly acidic.

The only drawback is the inability to use certain types of units for processing nutmeg varieties.

Instructions and drawings on how to make it yourself at home

To crush a small crop (up to 500 kilograms), it is enough to build a wooden crusher with your own hands according to the proposed drawing. Its production consists of the following stages:

After this, the final assembly begins. A support frame with rollers and an upper hopper are attached to the container with the mixture. A handle is attached to one of the roller axes. With its help, the crusher is set in motion. All parts are coated with colorless wood varnish. It must be non-toxic and safe.

In the future, the finished press can be upgraded by adding an electric drive. Additionally, you will need a belt and transmission shaft, and a suitable engine. From a manual form, this form turns into an electric one, which increases efficiency.

Video: homemade manual grape crusher - device

This video talks about a grape crusher and how to crush grapes.

conclusions

Grape crusher is a unit designed for the production of juice and cake. These are the ingredients for making homemade wine and other products.

Before purchasing a crusher, it is important to consider the following nuances:

- All options are divided into 2 main groups: mechanical and electrical. They have almost the same principle of operation.

- The basis is a container for cake, a frame with grinding elements, and an upper part in the form of a bell. A gap is made between the rollers, often adjustable. With its help, the seeds are not crushed, which increases the quality of the cake.

- The choice of model depends on the type and volume of raw materials. To process a small amount of berries (up to 500 kilograms), the simplest form is sufficient. For production on an industrial scale, an electric version will be needed. You will also have to purchase and or make it yourself.

- There are options with and without the comb separation function.

- Allows you to obtain clean pulp without impurities, saving raw materials, time and effort.

- The simplest variety can be improved if necessary.

The simplest variety can be made with your own hands. A wooden form is the simplest manual option. If desired, it can be improved by adding additional elements.

After the grape harvest is harvested, many gardeners, especially those cultivating technical varieties, begin making homemade wine. At the first stage, of course, you will need to chop the berries, crushing them to a pulp.

If previously it was customary to crush berries directly with your hands or feet, now this not very hygienic method has been replaced by modern units - crushers. They made it possible to automate labor and save effort and time in the production of large quantities of the alcoholic drink beloved by many.

Purpose and principle of operation of the crusher

Almost all crushers for crushing berries have a very simple, but at the same time effective design. The units consist of a receiving hopper for loading, a pair of parallel crushing rollers and a container for collecting pulp.

The volume of grapes required for processing is loaded into a special receiving container. Then, mechanically or electrically, the crushing rollers are brought into operation, crushing the grapes and transporting them to the pulp collection.

The main features of such a unit are the presence of a gap between the teeth of the crushing rollers, as well as their rotation in different directions.

The gap allows you to leave the grape seeds intact, which is very important for obtaining quality wine. Damaged seeds give the finished drink excessive bitterness, which is due to too much tannin in them.

Types of crushers

Today it is possible to purchase wooden, plastic or stainless steel crushers for grapes. The main condition for a high-quality unit is the manufacture of parts involved in the process of crushing berries from materials that are not subject to oxidation. The simplest option is a wooden crusher.

A more convenient and modern option is a manual or electric crusher equipped with a destemmer. Stainless steel crushers are characterized by high quality and are very easy to clean and wash.

Grape crusher (video)

Grape combs can give wine the astringency and richness characteristic of quality drinks. However, their excess amount very often causes the drink to taste bitter or unpleasant, and also negatively affects its color and transparency. And if, when making red wines, it is allowed not to remove the grape stems, then for white wines such a procedure is mandatory.

There are two main types of destemming crushers used for grape processing.

Roller crushers-comb separators

Such a unit best meets the requirements of the technology for preparing raw materials for wine and allows you to obtain high-quality must. Our country has launched the production of such crushers. The operating principle is based on the operation of rollers and a destemmer. A pair or more horizontal rollers are cylindrical in shape and rotate in opposite directions. The size of the gap between the rollers is regulated by a special device. Rolls have a grooved, smooth or bladed surface and can be four-, six- or eight-bladed. Preferably profile rolls are used.

Centrifugal impact crushers-stemmers

Centrifugal crushers, or CDGs, can be either vertical or horizontal. The process of crushing grapes occurs as a result of impacts of a rotor rotating at speeds of up to 500 rpm. The use of this type of crusher-stemmer is characterized by the most complete yield of wort with an increased amount of coloring and phenolic substances. As a rule, CDG is used in the production of wine from red grapes.

Mechanical and electric crushers

The operating principle of a standard electric crusher has minor differences from the operation of a mechanical device. A special feature is the presence of a special comb separator, which is a horizontal cylinder with a shaft and helical blades. Such elements allow you to quickly and efficiently separate grapes from the ridges. As a result of the translational movement of the screw blades, the ridges are pushed outward. Only juice and clean grapes enter the crushing container.

Advantages of using crushers

A grape crusher is a useful and practical unit for those involved in winemaking. Using such a device in wine production has a number of advantages:

- reduction in technological loss of pulp by several times;

- absence of saturation of the pulp with components undesirable for the final product;

- saving time and effort;

- obtaining higher quality pulp;

- the design of the unit is simple, reliable and very durable;

- a manual or mechanical crusher can be used in the absence of electricity;

- The high-quality stainless steel crusher is reliably protected from corrosion and does not impart any foreign odors to the grape juice.

It should be remembered that crushers equipped with destemmers are not used when processing Muscat grapes.

Making a crusher with your own hands

A simple, but quite technologically advanced grape crusher is quite easy to make with your own hands. When making small volumes of homemade wine, there is no point in purchasing a factory design, which, by the way, is quite expensive. Making such a unit yourself will take a little time, and in terms of efficiency it will be almost as effective as devices sold in stores.

Instructions for making a crusher:

- The body can be made from any material, the most preferred option is high-quality oak boards.

- Making a drum, or beater shaft, from a pipe and equipping it with stainless steel blades 1.5 mm thick

- Manufacturing bearings in the form of plastic bushings with longitudinal slots, which will allow you to change the size of the gap between the drum and the deck.

- Installation of the drum using a metal rod with a diameter of 1.4 cm on bearings in the form of plastic bushings for sliding.

- Installation of a concave or deck under the beater shaft, the dimensions of which depend on the size of the berries. Most often, a grid on the deck with a cell of 7.5 x 14 mm for small berries and 12.5 x 25 mm for large grapes is used.

- Installation of a handle with which the beater shaft on bearings will be driven.

The manufactured manual crusher is installed on a container for collecting pulp. Almost any container can be used as a pulp receptacle, but preference should be given to barrels or tanks made of food-grade plastic or stainless steel.

DIY grape crusher (video)

Both a purchased and a self-made unit for crushing grapes will become an indispensable assistant for winemakers. It not only speeds up and facilitates the process of preparing the pulp, but also helps to obtain a more transparent, tasty and aromatic homemade wine.