Stove potbelly stove from a pipe for cooking. Long-burning potbelly stove: a simple design for making your own hands

A horizontal potbelly stove from a pipe is one of the simplest, but most productive designs of home-made solid fuel stoves. The simplicity of design and low cost allow even novice home craftsmen to make such an oven.

Collapse

First, beginners need to understand how the oven works, what parts it consists of.

Principle of operation

The principle of operation of such a furnace is simple:

- firewood is laid in the firebox;

- for kindling, thin chips are placed closer to the door;

- the door in the ash pan and the slide gate must be open;

- firewood is set on fire and the door is necessarily closed;

- the flame heats up all the planes of the furnace. Metal, giving off heat, gradually heats the room;

- for the second bookmark, you can use coal or carpentry shop waste.

Stages of work

Before starting work, it is necessary to determine the size of the furnace, and prepare necessary materials, tool and welding equipment.

Drawing and scheme

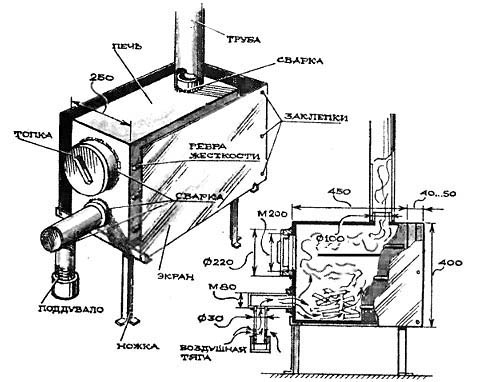

Drawing of a potbelly stove from a horizontal pipe

Another version of the drawing

The most simple stove from the pipe runs on solid fuel and consists of several main parts:

- case - it is made different in shape, depending on the materials used for its production. It can be rectangular when using sheet metal or cylindrical, in this case, the body is made of gas cylinders or pipes of large diameter;

- grate. It serves to protect the bottom from burning through and remove ash to a special compartment;

- ash pan - wood ash is collected in this part, this cavity serves as a blower to improve traction when firewood ignites;

- combustion chamber. Firewood or coal is laid here;

- To remove carbon monoxide, stoves are equipped with a chimney pipe outlet. In some cases, it is displayed vertically from the top of the furnace or with a branch coming out of the rear plane. But in any case, the chimney outlet is located at the top of the structure;

- above the door, install a reflective screen. It is placed along the entire plane of the furnace, leaving the air passage in the rear cavity. In this case, the heat does not immediately go into the chimney, but passes through the furnace, heats the walls, and only then enters the chimney;

- combustion chamber doors. Here they use ready-made cast-iron or steel doors or home-made ones from a piece of thick metal;

- the most efficient potbelly stove equipped with additional convection pipes, drawings of such homemade oven can be found on the forums on the Internet or check out the industrial furnaces of Professor Butakov or the Bullerian model.

A potbelly stove from a pipe with an inner diameter of 500 mm is made according to the drawing, taking into account the main dimensions of the structure:

The dimensions of the remaining parts and their installation locations will be taken from the drawing.

Let's analyze the process of making a homemade stove.

What pipe do you need?

Any pipe can be used. Most importantly, it should not be used previously on gas supply pipelines and for sewage. Such stoves, together with heat, will distribute throughout the room unpleasant odors long time. In size - it all depends on the needs and capabilities of the master.

To heat a small garage, it will be enough to make a stove with a diameter of 400-500 mm. For large room you can make a potbelly larger diameter or install a few small ones. The main thing before work is to clean the walls from limescale, dirt or oil and only then proceed to work.

Materials and their quantity

For the production of a potbelly stove, we need to prepare:

- steel pipe with a cross section of 550 mm, with a wall thickness of 10 mm - length 650 mm;

- for the top of the furnace from steel 4-5 mm, we cut out a workpiece 700/420 mm and bend it along the length of the shelf, marking 40 mm from the edge of each side;

- front and rear walls of the potbelly stove - 2 parts, 560/560 mm in size;

- for a reflective screen, we cut out a blank from a sheet measuring 500/420 mm;

- for the grate, it will be necessary to prepare reinforcement, with a section of 10 mm - 2 parts of 600 mm each and 32 pieces of 380 mm each;

- to output the chimney, we prepare a pipe section with a cross section of 100 mm, a length of 260 mm;

- at the top there is a cooking burner. You can use ready-made cast iron or make it from a steel sheet 12-14 mm thick by cutting a circle with a diameter of 220 mm with a plasma cutter and turning the workpiece on an emery or grinder;

- from a profile of 40 mm we prepare 4 legs 400 mm long;

- we buy ready-made loops or you can make it yourself from a profile and a bar;

- for a door from a sheet, we cut out a blank 340/340 mm;

- 6 segments of the corner for laying the grate.

This is a list of basic materials, small parts will be made as we go.

Tools and equipment

We will need:

- a set of locksmith tools;

- welding machine with clothing and eye and hand protection"

- grinder with a cleaning and a supply of cutting discs;

- workbench with vise;

- sand for backfilling the bottom of the furnace.

Step by step instructions for making

Having prepared for work the entire set of tools and materials, we proceed to the process of making a potbelly stove from a pipe with our own hands:

- We place the finished pipe section on a flat surface, set it protective screen at a distance of 5 mm from front side and grab it to the pipe. Here it is important to have experience in performing ceiling tacks, although there is practically no load on the screen. We put tacks through 60-80 mm.

- At the bottom of the furnace, we retreat 50 mm, mark the longitudinal lines along the entire length of the pipe and grab the corners for laying the grate. For its manufacture, we place long parts from reinforcement, insert jumpers along the edges and grab them. Now, retreating from the jumper 10 mm, we join the next jumper. Thus, we collect a lattice of reinforcement, 600/400 mm in size. After that, turning the grate over, put the potholders on the back side.

- We put the grate of the grate in place and join the sheets of metal from the front and back sides. Skew and large gaps between the sheet and the pipe should not be allowed. If the pipe is cut crooked, you will have to level the workpiece by turning the walls with a grinder. After checking the correctness of the assembly, we proceed to welding the joints. The seam must be airtight, so after welding, beat the slag and boil the burns, shells and lack of penetration.

- There is another option for installing a grate that is more practical. A rectangle is cut out at the bottom of the pipe with small indents along the edges, a workpiece from profile pipe(to collect ashes). A grate is placed on top. Here's what it looks like:

- We grind the protruding corners and the junction of the parts with a cleaning stone. Then we turn the blank face up and mark the opening for laying firewood. We put a cutting disc on the grinder and cut a groove along the markings.

- We remove the burrs with a file, lay out the door with a welded handle and latch and install it on the finished loops. On the sheet we expose and grab the reciprocal part of the lock, and on the door we expose a home-made lock - a latch.

- We turn over and place the potbelly stove with the bottom up, mark and weld the legs from the profile pipe, having previously cut the corners for better joining to the body. At the bottom, we cut the legs at a small angle and weld nickels from the sheet, for better stability of the potbelly stove.

- We install the stove on the legs and put a blank on top of the stove with holes for the chimney pipe and burner. Having placed it with the curved edges down and checking the correct installation, we grab the plate.

- We burn holes in the pipe with electric welding and install a pipe with a diameter of 120 mm for the hood and a pancake for pans.

- Parts are scalded in a circle, the joints must be tight. At the end of the ventilation pipe, we weld a slide gate to control the draft.

- Opening the door, setting the grate in place, we fill the bottom of the furnace with a layer of sand.

The stove - a potbelly stove from a pipe is ready.

Look at a few more manufacturing options to consolidate understanding:

Operation features

When testing the potbelly stove, it is better to open all doors and windows. We make sure that there is traction and an open damper. Then, laying firewood through the door, we light the flame. We close the door and go outside. The potbelly stove will smoke pretty much, but you should not be afraid of this, it will burn out oil and other debris.

Furnace process

After using the oven for the first time, welding defects may need to be repaired. And then enjoy the warmth in the garage or other room. The main thing to remember the rules fire safety, periodically clean the chimney and remove the ashes, periodically replacing the sand in the potbelly stove.

Conclusion

To make such a design on your own is quite within the power of even a novice master. The main thing is to want to make a reliable potbelly stove and carefully and responsibly perform all the work, taking into account the step-by-step instructions given in the article.

←Previous article Next article →The potbelly stove is an iron, compact dimensions oven with a chimney at the top. It consists of a chamber where it falls asleep solid fuel, a grate in the form of a metal grate, a pipe - a chimney and an ash pan for collecting ash.

With the ability to handle the welding machine, the device is easy to manufacture, while it will serve faithfully in unheated room, in field conditions, in the absence of centralized heating for more than a dozen years.

How to do it yourself?

Manufacturing options:

Rectangular oven

It is a metal box, you can independently weld the structure of steel sheets. For a rectangular potbelly stove, an old automobile tank, a box will fit perfectly.

Usually, this form is chosen when it is necessary to cook food on the stove.

On a spacious platform, you can put 2 at once large pots or containers for heating water.

The manufacturing principle is simple: doors are built to cover the blower and the combustion chamber, a hole is made for the chimney, combustion products must leave the room in a timely manner, otherwise you can inhale carbon monoxide.

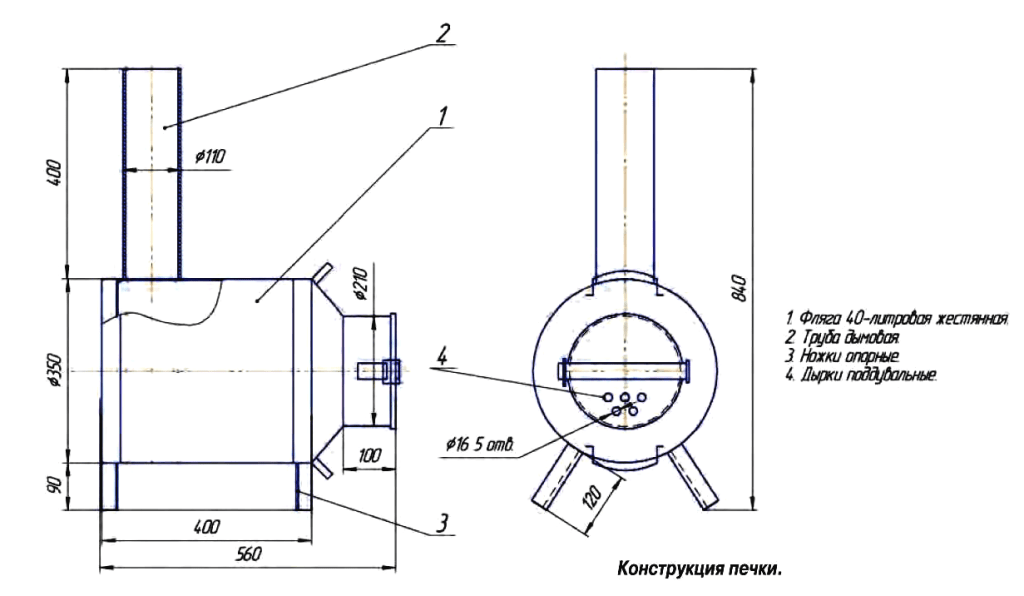

From a gas bottle

The most common type of potbelly stove. The cylinders have thick walls, the furnace is durable, mobile, fireproof.

First, a drawing is drawn, markings are made. The door for the combustion chamber will be located in the center of the cylinder. It blew in the same plane, only 10-12 cm lower.

Instruction:

- We take a grinder, cut out both doors, draw a closed line between them.

- Along the line we cut the balloon into 2 parts.

- At the bottom We weld the grate - blower.

- Install grate, weld both parts again.

- for valve make a hole with a radius of 10 cm.

- for hood we insert a hole into the pipe, by welding we weld objects.

- simple stove from the cylinder is ready, you can use it, throw in fuel and check its operation.

For cooking on the top of the stove, the design is slightly different:

- cut off the top of the balloon.

- Inserted inside and welded rods.

- Side top cut a hole for the pipe. You can heat and cook food at the same time.

- Welded hole, the valve is screwed in, a comfortable handle adapts.

- From a pipe, barrels can also be done oven. The barrel or pipe must be selected according to the diameter.

- At the bottom of the barrel pipes cut 2 holes for the firebox and ash pan.

- Make doors.

- Do framing metal strip holes.

- Under the furnace door at a distance of 10 - 12 cm inside the barrel, weld brackets at the corners, a grate will lie on them, weld it first from any fittings.

When making a furnace from a pipe, weld the bottom of it, as well as a part on top:

- Down to the bottom weld 4 legs.

- On a surface cut a hole, weld a pipe to it, this will be a chimney.

- Weld hinges to the previously cut holes, install the doors. Also, mark and attach a hook so that the doors lock tightly.

- For design aesthetics finish all welding seams, clean them 10. Paint the outside of the device with heat-resistant paint. Whatever factory product, you can sell or successfully use yourself.

Working furnace

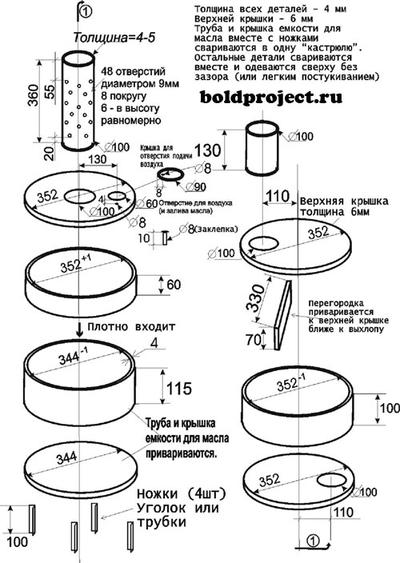

The option is distinguished by a specific smell, which during the combustion of fuel will be emitted by oil mining, even in the presence of an exhaust hood.

Instruction:

- To make this model , select sheet material with a thickness of at least 4 mm, a chimney pipe, individual small structural elements.

- Do it on a sheet accurate markings of all elements, having previously drawn a drawing.

- embed all elements with a grinder, clean the edges of the parts. Drill holes round shape in the pipe.

- Top of the tank cut the pipe hole off-center to the left.

- Shifted to the right on the circumference, drill a hole for the connecting pipe.

- Got 2 circles, weld them to the pipe, the thickness of the upper tank will depend on its segment.

- Decorate the bottom part of the stove in the same way., but now cut the hole right in the center of the marked circle.

- cut next second hole, attach the sliding cover to it.

- Weld to the bottom plane 4 legs.

- Clean seams after welding, paint the surface with high temperature resistant paint.

- Connect the chimney to the oven. The mining will be poured into the lower part of the tank, after the paper is ignited, the sliding cover closes, and the mining starts to burn. Oxygen will penetrate through the holes, mining will burn intensively.

Necessary materials, tools

Before starting work, prepare the tools:

- metal brush;

- chisel, pliers, hammer;

- tape measure, chalk;

- drill with drills for metal;

- grinder;

- circles for metal;

- welding machine;

- protective mask;

For the case you will need a pipe 30 cm in diameter, at least 5 mm thick. You can use sheet metal of the same thickness instead of a pipe.

For the chimney, you should choose a pipe 12 cm in diameter, at least 3 - 4 mm thick. To avoid burning out, a metal box is suitable for the ash pan, so you need to choose a durable sheet metal.

Walkthrough

First you need to cut the metal, taking into account the thickness and length of the desired blanks.

Chamfer parts from parts, the touch to the furnace will be safer, and the welding seams will be strong:

- Check the correct markings of the parts before you start cutting them. When cutting, consider the thickness of the walls of the furnace, also the circle.

- Bevel the prepared parts to prevent accidental contact with the hot device.

- Check all part markings.

The design is installed in the following sequence:

- Connect welding machine to the network.

- Take electrode with a thickness of 4 - 5 mm, taking into account the sheet or pipe.

- Install current strength on the device up to 160 A.

- put on special glasses and overalls, protect your hands with leggings.

- To the bottom of the oven weld three walls.

- Bottom of device place at least 5 cm from the floor.

- connect parts at right angles. Check their perpendicularity with a level.

- Where needed, straighten the corners of the details.

- weld details and joints relative to the floor level, at an angle of 45 gr.

- weld a partition between the blower and the firebox, having previously cut holes so that ash does not accumulate.

- withstand the distance between the holes is at least 5 cm from the walls of the stove. The distance between the partition and the bottom of the structure must remain at least 10 cm.

- Lastly by welding, cut holes for installing a chimney on the back of a homemade stove.

- Make markings, drill rectangular holes in the places intended for the firebox and blower.

- Align with baffle all bottom holes. The distance between the walls of the furnace and the upper side edges should be at least 3 - 5 cm. The opening for the blower is slightly smaller, but not more than 5 cm.

- Bulgarian cut two holes from metal, form doors. Weld them on the canopies, raise the blower to the maximum to the top of the slab opening so that they do not sag further under the influence of high temperatures.

- To the doors weld bolts, they should open and close easily, without obstacles.

After all welding work check the quality of the seams, tap them. If there are defects, correct them immediately. At the end of the work, weld upper part devices.

How to make a potbelly stove of long burning?

In order for the potbelly stove to radiate heat for as long as possible without throwing another portion of firewood, it does not burn out quickly, it is possible, the fuel will not burn, but smolder, the heating process without laying firewood can be extended for several hours.

Making a furnace for long burning slightly different from the usual design.

A balloon is best suited for the furnace:

- Cut off the top of it, this will be the lid of the stove.

- Punch a hole at the top and side of the stove, this will be the hood.

- Punch a hole in the center so that the balloon can be easily inserted.

- weld to the cut hole of the pancake pipe, a little longer than the cylinder. The pipe will serve as a blower, and oxygen will flow into the furnace, the fuel will not smolder, but will not burn.

- cut off part of the balloon in the center, insert the pipe into the hole as a blower. The principle of operation of a potbelly stove for long burning is to create pressure inside the chamber. After the firewood flares up, a heavy metal circle sinks inside, begins to put pressure on the fuel, creates pressure on it, the fuel begins to experience a lack of oxygen and slowly smolder. The smoke, heading up, goes out through the chimney, the room will not be smoky.

Advantages and disadvantages

Like any other heating device, the stove has both pluses and minuses.

Like any other heating device, the stove has both pluses and minuses.

The undoubted advantages of a homemade oven are:

- Compact dimensions.

- Use of any available fuel, you can heat with peat, firewood, sawdust, wood chips, coal.

- Insignificant costs for the manufacture of the device, basically you can get by with handy materials.

- Construction installation does not require laying the foundation, chimney.

The disadvantages of the oven include:

- Enough high flow fuel material, the principle is as follows: while you are drowning, it is warm. To keep the room cool, you need to throw fuel more often, otherwise you can just freeze.

- Furnace walls become very hot and may result in burns if touched.

- Should not be allowed coals falling out of the oven, this is fraught with fire.

Where can it be applied?

Furnaces were popular in the first half of the last century. They warmed the soldiers' dugouts, dugouts, and heating wagons.

Today stoves are still heated garden houses, garages, warehouses, greenhouses, that is, where there is no gas pipeline, and electrical devices are inefficient and consume a lot of electricity.

Types of homemade bourgeois

The material for the construction is cast iron or stainless steel. The furnace consists of a container, an ash pan, a branch pipe, a chimney, a furnace door.

The types are distinguished:

- pyrolysis ovens;

- with a cooking platform at the top for cooking;

- furnaces sheathed with a casing for efficient heat transfer. For homemade, you can choose old cylinder, barrel, big vat, can. Furnaces can be cylindrical, rectangular;

Installation safety rules

Any home-made heating device is designed to heat the room, making it more comfortable, but along with this, such devices are far from safe, fraught with ignition, fire.

When installing the structure, it is very important to follow the safety rules:

- Bake must be installed on a surface that is resistant to fire, otherwise the floor may burn through. For this, it is good to lay bricks and tiles on the floor.

- The walls of the stove should not overheat much; for this, special drywall or other non-combustible material is used in the manufacture.

- Fast flammable materials do not put near the firebox, they can catch fire.

- take care about ventilation in the room where the potbelly stove will be located. Carbon monoxide should go outside in a timely manner, and not accumulate inside the room.

- use in production only high-quality, refractory material.

- In the presence of panel, wood walls in the house install the oven at a distance of 1 meter from them.

- Be sure to mount chimney preferably from one section.

- When running a pipe through a wall install a brick thermal barrier. Do not use concrete for these purposes, it crumbles quickly.

- for garage better fit the potbelly stove is working off, so do not rush to throw it away rims from wheels.

- Don't put the oven near flammable materials.

- pipe section just above the roof, follow from non-combustible material, so the oven will cool down much more slowly.

- Think well ventilation system, the room should not be burning.

- Lay out the floor and walls near the structure with a brick, or facing material, the stove is fire hazardous The same applies to the chimney, the distance to the walls and ceiling must be at least 1.2 meters.

- Install for safety metal guard around the device.

- grate it is better to make it from cast-iron grates in a set, so it will be easier to pull them out of the furnace.

- Install all parts of the chimney only at the top of the structure, they must withstand high temperatures over 300 degrees.

- Work the seams after welding with a durable and high-quality sealant.

- Do not brush the pipe, metal objects, the pipe walls can quickly leak.

- Mounting the chimney, make a rain visor, rain moisture will not get inside the pipe.

Very often, a potbelly stove is used to heat the garage. And you can do it yourself, but you don’t need to spend money for this. It is enough to look in the bins for unnecessary metal parts.

Advantages and disadvantages of a potbelly stove for a garage

The potbelly stove is rightfully considered the most practical way heating in winter. This is a small design, which is practically portable, capable of heating any room, regardless of the temperature outside and other climatic conditions. This is its main advantage. However, in modern conditions a potbelly stove is used exclusively for heating outbuildings, for example, a garage. And it is connected with large quantity disadvantages:

- the stove cools down quickly, which means that in order to maintain a constant temperature in the room, it must always be on;

- uneconomical for the same reason;

- fire hazard, so when installing it, care must be taken to protect the nearby wall and floor.

However, its omnivorousness allows you to save a little on the purchase of fuel, especially considering the almost 100% efficiency of such a device.

The potbelly stove has a special design, thanks to which you can get high efficiency

Design and principle of operation

The peculiarity of the stove-potbelly stove is that it does not require the construction of a foundation and the arrangement of a capital chimney. In most cases, it is because of this that it is chosen for use in the garage. This room does not always have electricity or a gas pipeline, which means that a potbelly stove is the only solution to the heating problem.

Potbelly stove does not require the construction of a foundation

This design is metal box with a door and a pipe that is led outside the heated room.

The pipe can also serve as a heated element, if you modify it a little. Make it stepped rather than straight, which will allow hot air to linger in it a little.

Calculation of basic parameters (with drawings and dimensions)

The high efficiency of a potbelly stove can only be obtained if all the main design parameters are correctly calculated.

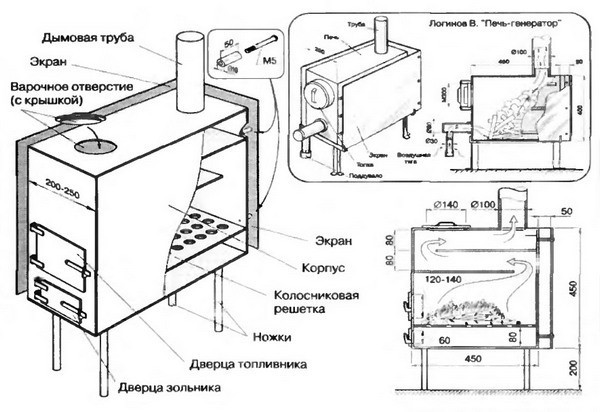

Pipe

In this case, the diameter of this element is very important. Bandwidth chimney should be less than the performance of the furnace furnace, which is the main distinguishing feature potbelly stoves. This will allow warm air not immediately leave the stove, but linger in it and heat the surrounding air.

It is very important to make exact calculation for her. The diameter should be 2.7 times the volume of the firebox. In this case, the diameter is determined in millimeters, and the volume of the furnace in liters. For example, the volume of the furnace part is 40 liters, which means that the diameter of the chimney should be about 106 mm.

If the stove provides for the installation of grates, then the height of the furnace is considered without taking into account the volume of this part, that is, from the top of the grate.

Screen

It is very important to make the hot gases not cool down, but completely burn out. In addition, the fuel must be burned by partial pyrolysis, which requires an extremely high temperature. A metal screen, which is located on three sides of the stove, will help to achieve a similar effect. You need to put it at a distance of 50–70 mm from the walls of the stove, so that most of the heat will return to the stove. This movement of air will give the necessary high temperature and protect from fire.

The screen of a potbelly stove made of red brick is able to accumulate heat

bedding

She must be. There are two reasons for this:

- part of the heat is radiated downward;

- the floor on which the stove stands is heated, which means there is a risk of fire.

The litter solves two of these problems at once. It can be used as a metal sheet with an extension of 350 mm (ideally 600 mm) beyond the contour of the furnace itself. There are more modern materials that do an excellent job with this task, for example, a sheet of asbestos or kaolin cardboard, at least 6 mm thick.

Asbestos sheet can be used for bedding under a potbelly stove

Chimney

Despite all the calculations, gases sometimes go into the chimney not completely burned out. Therefore, it must be done in a special way. The chimney consists of:

- vertical part (1–1.2 m), which is recommended to be wrapped with heat-insulating material;

- burs (slightly inclined part or completely horizontal), 2.5–4.5 m long, which must be 1.2 m (from wooden surface by 1.5 m), from the floor - by 2.2 m.

The chimney must be brought outside

Photo gallery: diagrams for a potbelly stove for a garage

On the diagram you need to indicate all the exact measurements

On the diagram you need to indicate all the exact measurements  The chimney must be led outside

The chimney must be led outside  Potbelly stove can be round or square

Potbelly stove can be round or square  The volume of the furnace depends on the presence of grate

The volume of the furnace depends on the presence of grate  The scheme of the potbelly stove depends on the material used

The scheme of the potbelly stove depends on the material used

Necessary materials and tools

To make a potbelly stove with your own hands you will need:

- welding inventory (or any other welding machine if you have relevant experience);

- chisel;

- soft cloth (you can use rags);

- a hammer;

- sandpaper (fine-grained).

The list of materials depends on what capacity the potbelly stove will be made from. It could be gas bottle or a milk bottle. If you have some experience working with metal, then a potbelly stove can be made from sheet material. However, you definitely need to take care of the availability:

- refractory bricks;

- steel pipes;

- metal wire;

- grate (in some cases, you can do without them);

- branch pipe with a wind vane;

- door hinges.

Preparatory work before assembling the furnace: choosing a place

Using a potbelly stove in the garage, like any other heater, requires compliance with safety rules. First of all, this concerns the installation location of the device. The corner of the garage, which is located near the walls opposite to the gate of the room, is ideal for this.

Remember that you can not put the stove in close proximity to the car. The distance between them should be at least 1.5 m. A similar distance should be from objects that are easily flammable, for example, from barrels of gasoline.

The walls near the potbelly stove should be protected with refractory material

The distance from the potbelly stove to the wall depends on what material the garage is built from. If it is a tree, then there should be at least 1 m from the stove to the wall. In addition, it is recommended to protect them with asbestos slabs.

Do-it-yourself step-by-step instructions for making a potbelly stove for a garage

The method of manufacturing a potbelly stove depends on its shape and the material used.

Classic stove-stove

For the manufacture of such a design, it is necessary to have certain skills in working with a welding machine. All work consists of several steps:

- Make 5 blanks from sheet metal.

Blanks need to be cut from sheet metal

- weld side surfaces to the bottom. Make sure that they are located strictly vertically relative to each other, which will help the use of a level or building square.

- Weld the back wall.

- The internal space is conditionally divided into three parts: smoke circulation, furnace part and ash pan. In the last two, install a grate. To do this, at a height of 10-15 cm, you need to weld the corners over the entire length. For the grating itself, it is recommended to use thick sheet steel 25–30 mm wide, from which strips must be cut. The distance between the plates should be 5 cm. The rods themselves must be welded to two rods, which give the lattice rigidity.

- From above it is necessary to weld two metal rod, which are needed to locate the reflector (a sheet that separates the furnace and smoke circulation), the reflector must be positioned in such a way that a channel for smoke is formed.

Grid-irons and a potbelly stove are not obligatory elements

- Weld the lid of the potbelly stove, not forgetting the hole for the pipe. Cut and weld the top jumper. Do the same with the narrower part.

- Make a door. It is recommended to do it over the entire width of the stove so that the grate and reflector can be removed without problems during cleaning and repair. Do not forget that the door must be equipped with a handle, latch and curtains.

- Install the structure on legs, which can be made of metal pipe 2–3 cm in diameter. You should not make them too high. 8-10 cm will be enough. If desired, they can be equipped with bolts, which will allow you to adjust the height.

- Make a chimney from a pipe with a diameter of 15–18 cm. To output it, you need to make a hole in the wall of the appropriate size. The pipe consists of three parts, which are connected to each other at an angle of 45°.

The pipe must not have horizontal parts

- At the lower end of the chimney it is necessary to make a rotating damper. It can also be made from sheet metal, but the diameter should be slightly smaller than the hole in the pipe. You also need to provide a handle that would move this damper.

- You need to fix the pipe on a sleeve measuring 15–20 cm, which is welded through the hole to the top cover.

- Install the stove, adjust its height.

When using sheet metal, you can make a potbelly stove of any size

Video: do-it-yourself original potbelly stove for a garage

Milk can oven

Making such an oven is quite easy, you just need to follow the step-by-step instructions:

Video: potbelly stove for a garage from a gas cylinder

Operation features

During the operation of a homemade potbelly stove, it is very important to observe certain rules. This is necessary not only for the safety of its use, but also for a long service life. Those rules are:

- it is necessary to maintain a safe distance between the walls of the furnace itself and the walls of the room (a distance of 50 cm is considered ideal);

- the chimney must be taken out exactly to the street, in no case should it be matched with ventilation system garage (very often this desire arises when the stove is installed in the basement of the garage), since this is the only way to guarantee sufficient draft for full combustion;

- places where the pipe is brought out into the street must be insulated with asbestos or other non-combustible material;

- you can increase the efficiency of the potbelly stove by insulating the room itself;

- next to the potbelly stove, it is necessary to install a box of sand and a fire extinguisher, as this is required by fire safety rules.

How to improve oven performance

Such an oven has one significant drawback - it cools down very quickly. However, this is very easy to fix with a brick screen that is installed on three sides of the structure. This will allow you to accumulate heat and give it to the room even after the stove stops burning.

You need to place it at a distance of 5-7 cm from the walls of the stove, in no case back to back. In this case, you need to take care of the presence of ventilation holes.

The screen should not be close to the walls of the stove

A construction with a brick screen will weigh much more than a conventional metal potbelly stove, so it is recommended that you first build an individual foundation.

In some cases, it may be necessary to install an individual foundation. Making it is very simple:

- Dig a hole about 50 cm deep. All other dimensions depend on the size of the stove itself and the screen.

- Fill the bottom of the pit with sand (usually it takes about 3-4 buckets), after which it needs to be rammed. Cover the sand with a layer of crushed stone 10-15 cm, also tamp.

- Level the backfill, pour cooked cement mortar. Leave for a day (it is possible for several, the foundation will only benefit from this).

- Cover the base with several layers of roofing material.

- Now you can start laying out the screen in a brick floor. In this case, the first two rows should be laid out in continuous masonry directly on the roofing material. In the 3rd-4th row, it is necessary to make ventilation gaps. Continue continuous laying.

- The screen is recommended to do without the top overlap.

How to properly clean a stove

The design features of such a stove make it possible to clean it quite rarely.

This is one of the advantages of the potbelly stove. However, periodically the chimney must be cleaned of soot residues. To do this, you can use a special brush. You can make it yourself. Attach a cylindrical brush to the rope. It is recommended to take a brush with plastic or iron bristles. At the same time, you need to pick it up in such a way that it squeezes into a narrow chimney pipe without any problems.

The cleaning process itself occurs in the following sequence:

- Close the opening of the firebox and plug it with a rag.

- Make several movements with the brush (you need to stop when the brush began to move without resistance). Wait.

- Remove any food that has gone down to the sump.

All this must be done very carefully, since the chimney of bourgeois women is not very strong.

A homemade potbelly stove in the garage can become reliable and effective assistant in the fight against winter frosts. And if you do it yourself, then the efficiency of the device can be increased many times over.

In Russia, then the USSR, potbelly stoves were used where there was no centralized heating: in front-line dugouts and dugouts of the Great Patriotic War, in state institutions of the same time, in heating cars. See a photo of a potbelly stove made by yourself on the website.

Who are the authors of homemade products?

Many Russians are sure that this is only a simple Russian invention. And some are wrong. In the United States, the same homemade products have been used for centuries, being called "fat belly", in Japan - "darums".

The revival of bourgeois women took place in Russia in the second half of the 20th century due to the massive appearance of garages, garden plots, where they were the only means of heating thin-walled buildings.

After the improvement of these mini-ovens - and for cooking: a pot or pan was placed on a stove attached to the top.

Until they were replaced by a centralized supply of methane, gas-balloon stoves or wood-burning bricks. They also came in handy in the 90s of the crisis years due to interruptions in gas and other types of fuel. It's good that at least there was plenty of firewood.

What is attractive bourgeoisie?

Its main feature is the simplicity of the design. Even with many additions to it, the principle of operation metal stove remains the same: everything that is at hand burns and heats summer residents.

Although at the same time half of the thermal energy escapes through the direct-flow pipe. But no one writes off even a heating source that has rusted from time to time.

It is easy to make such a temporary stove in a day or two. But first draw up the drawings of the potbelly stove with your own hands. Much of what is stored in the closets of rural houses and dachas goes into action. These are milk and water metal (but not duralumin) cans, barrels from diesel fuel, vegetable oils, pipes, boxes, corners.

Nothing expensive, including a tool - in the villages every owner has it at hand. High-quality assembly using gas or electric welding.

But neighbors who have units will help with this. welding machines ensures greater reliability and rigidity of the assembly. How to make a potbelly stove with your own hands, step-by-step instruction below.

We make a potbelly stove from a steel can

Stock up on a hardened chisel, a hammer, a chimney, a piece of rod with a diameter of 0.6 - 1.0 cm. Prepare an electric drill with a drill one centimeter in diameter. If there is a grinder, you will speed up the assembly twice.

In one part of the cover, at the very bottom, drill 5 - 7 holes for future traction. Bend a long rod with a snake and with legs, at least four. These will be the grates when you insert them into the can.

Straighten the snake inside so that it lies horizontally and firmly just above the holes. Firewood will burn on this “grill”, and good air draft will go through the holes and with the help of a chimney. It will be the catalyst for combustion.

For the chimney, fit a piece of water pipe, even used, with a diameter of 7-8 inches. Near the bottom or on the very bottom, strictly perpendicular to the grate, cut through with a chisel or saw through a circle with a grinder.

Insert the pipe into it a few centimeters, and from the outside fix it tightly with a clamp on the bolts or weld it to the can. The can stove is designed for a horizontal position.

Weld legs to it and put it where the potbelly stove will heat the house, garage. This is a very flammable device, so place it on a metal sheet and at least half a meter from wooden structures.

The disadvantage of the stove: you can’t even heat the kettle on it - there’s nothing to put on. And yet it will be an effective potbelly stove with your own hands, and read about the improvements below.

barrel stove

She will correct the situation, and even cook borscht and fry cutlets on this potbelly stove. Suitable not only old barrel, but it is better if it is a decommissioned gas cylinder of 50 liters.

His walls are thicker, they will heat up a little longer, but they will also hold more heat. This is the perfect sauna heater. And if you impose sea or river pebbles, other strong stones, then it will be easy to raise steam in the room.

It will stand upright. The blower will also have enough space, and a lot of firewood can be laid in the firebox above it. The exhaust pipe can be made not straight, but with knees for a greater return of thermal energy in the steam room.

If a potbelly stove is needed for country house, then weld a metal platform on top, you will cook food and tea on it.

Preservation of heat in a potbelly stove

To do this, it is necessary to overlay two-thirds of its parts with refractory bricks, placing it on horizontal ribs, leaving Free access to the firebox and blower. It will be a heat shield that will keep the generated energy much longer. Holes must be drilled in bricks for better heat transfer.

The second option: a potbelly stove plus a water heater. Scald the gas cylinder from which the stove is made with sheet steel of at least three millimeters thick.

So that in the resulting container can hold at least 30 liters of water. Weld the water inlet and outlet pipes to it, connect the pipelines for heating the adjacent room. For better convection, connect a small circulation pump.

Propane stove

The perfect oven gas stove made by hand. She doesn't need chimney because no smoke is released when the gas is burned. Its analogue is room gas stove with oven.

It’s not difficult to make - take ... a finished potbelly stove, insert a steel pipeline with a nozzle from the old one into it gas stove. Connect it to a standard gas hose with a reducer from a household gas cylinder.

There is no exact consumption for a potbelly stove, you can navigate the stove for 4 burners. The capacity of the cylinder (for 50 liters) with 21 kg of propane-butane is enough for 34 hours of operation of such a stove.

DIY potbelly stove photo

Potbelly stove - perfect solution in conditions when it is necessary to provide heating of small-sized premises (garage, utility room, bath heating), spending a minimum amount of money. You can save money by using materials that almost everyone has, as well as by the ease of doing it yourself. Next, we will consider what a potbelly stove can be made of and give specific drawings.

What tool is needed?

Regardless of the selected drawing or design features potbelly stove, for work on its manufacture, in addition to materials, you need to prepare the following tools and equipment:

- A hammer.

- Bulgarian.

- Welding.

- Drill.

- Drill.

- Brush.

- Chisel.

- Pliers.

- Roulette.

It is understood that each of the listed tools is designed to work with metals.

Choose a view and get started

Potbelly stove can be made by hand from:

- Sheets of metal.

- Pipes.

- Can.

- Gas bottle.

The type is selected from the availability of materials, as well as the preferred complexity of the work performed.

Potbelly stove from sheets of metal

Here are the features of making a stove from metal sheets that use different raw materials for heating: mining and firewood.

Furnace in production

To start working with your own hands, a metal sheet of about 5 mm is prepared (it is this width that allows the stove to warm up quickly and effectively heat the garage) and pipes (needed for a chimney and some other elements). For a more accurate understanding of the manufacturing principle, see the drawing:

Let's get started:

- According to the given dimensions, it is necessary to cut out the elements from the sheet, from which the furnace will be made. Try to clean up the cut edges as much as possible.

- A part is being prepared for attaching the components of the potbelly stove - a pipe with holes.

- Parts of the upper tank are being prepared for the installation of a chimney pipe. To do this, according to the data given in the drawing, make a hole shifted to the left in relation to the center. Also, another hole is made at the bottom of the tank (shifted to the right) - it is intended for installing a connecting pipe.

- The constituent parts are welded together and a finished tank is obtained.

- The lower tank is welded in the same way. Only a hole is made to install the pipe in the center. You also need to make another hole with a slight offset - processing will be poured into it. A special sliding cover is made above the filling hole.

- The lower tank is attached to the upper one (they are welded to connecting pipe). Structural strength should be given with brackets.

- Do not forget to weld the legs to the lower tank.

- To increase the service life, the furnace is cleaned and painted.

Attach the potbelly stove to the chimney and try to heat the garage. To do this, pour fuel into the lower tank and set it on fire. When it flared up, you need to close the processing hole with a sliding lid.

Important: To paint the structure, use special heat-resistant paints.

Rectangular wood stove

This option is suitable when you need to heat a garage or sauna rooms designed for relaxation.

The features of the model, the manufacture of which we will describe further with our own hands, lies in the high heat transfer and the ability to adjust the traction force.

Our oven will measure 45x45x80. Such dimensions are enough to heat the average room. It will fit long firewood and is easy to move.

In this case, we will not give a specific drawing, and will try to explain as much as possible in words. Before starting work, we buy:

- Steel 3-4 mm thick. A sheet and a half by two meters will be enough.

- Piece of pipe. Choose from diameters from 90 to 100 mm. Length: 0.4 m.

- Rebar 16 mm. You need exactly 6.2 m.

- Five kilograms of electrodes.

- Four door hinges.

- A steel rod, half a meter long and about 10 mm in diameter.

- Seven meters of a corner with a 40 mm shelf. The walls must be 5 mm thick.

When everything you need is prepared, we begin to work with our own hands in the following sequence:

- The future walls of the structure are cut out of the sheets.

- The corner is welded in such a way that a frame is obtained. When performing this and the first paragraph, you need to remember the above dimensions of the stove (45x45x80).

- The reinforcement is cut and welded to the frame with an interval of 2 cm.

- The finished frame is scalded with tin.

- According to the diameter of a smooth bar in the pipe section, which will be the chimney, 2 holes must be made. The pipe is welded to the frame (before that, you need to make a hole under it).

- A curved rod is inserted into the chimney openings. It must be in the form right angle. A piece of round tin is welded to it, slightly smaller in size than the inner diameter of the chimney - it will be used for adjustment.

- The potbelly stove must have doors. They are cut straight out of the body. Loops are welded onto the removed piece of metal, with the help of which they are attached to the furnace.

- Bolts and handles are installed on the doors, which can be made of any convenient type. The main thing is that they guarantee the maximum fixation of the door (if you do not want to burn down the garage).

- When the work is finished, you can check the result of the work with your own hands and start heating the garage.

Important: To ensure traction, the doors are attached so that there are small gaps.

Potbelly stove from a pipe

This option implies the simplicity of doing the work with your own hands and aesthetic appearance, which will allow you to heat not only the garage, but also small spaces in the country.

Work algorithm:

- The pipe is taken and cut to the desired length.

- 2 holes are cut in the side part: for the ash pan and the firebox. The distance between them is approximately 15 cm.

- The cut out parts of the metal will serve as doors. Their size increases with the help of welding on top of metal strips. You also need to immediately install the handles that secure the door.

- Corner brackets are welded inside the future stove (the grate, welded with your own hands from reinforcement or bought in a store, will be held on them).

- The grate is installed.

- In the circle of metal that will close the pipe opening (the upper part of the potbelly stove), you need to make a hole for attaching the pipe (chimney).

- The bottom and top of the stove are brewed.

- The pipe is welded.

- Hinges are welded and doors are installed.

- The furnace in the places of welding joints is cleaned and painted with special paint.

- The last stage is the connection to the chimney brought outside the premises.

If everything is done correctly, the potbelly stove will be able to completely heat a garage or other small room.

can stove

From any old can, a potbelly stove can be made with your own hands. For this you need:

- Can.

- Piece of pipe.

- Armature or wire.

Let's get started:

- On a can installed in a horizontal position, we mark the location of a rectangular blower. It must be placed under the cover.

- Cut out a hole for the chimney. It can be in the bottom or wall.

- We make a grate. It is easier to make it from steel wire, which, in a bent form, is brought into the middle of the future stove and straightened. It is necessary to arrange the zigzag in such a way that it is most convenient to fill the potbelly stove with firewood.

- We attach the legs.

- We weld the chimney.

The design implies a minimum of manufacturing costs and you do not need to have professional skills to perform the work. With its help, you can safely heat the garage and other utility rooms.

Gas cylinder stove

If you have a gas cylinder lying around on your site, use it to create a potbelly stove.

Work sequence:

- Cut off the faucet and make a hole plug.

- Cut a hole in the bottom for the door. From the resulting piece of the bottom, with the help of scalding it with a strip of metal, doors are made.

- A lock-handle is attached to the doors and they are mounted on the cylinder using hinges that are welded.

- In that part of the cylinder, which will be the bottom, you need to make a grate. To do this, it is enough to make holes.

- A tin box is welded under the holes in the bottom, into which soot and waste will fall. Doors also need to be made in front of the box - they will be used to adjust the thrust.

- The stove must be raised from the ground with the help of legs. For their manufacture, an ordinary pipe is suitable.

- A chimney is welded into the upper part of the cylinder.

- If necessary, a hob can be arranged on the surface of the structure.

Such a stove will heat a garage or small house in the country.

A potbelly stove is a fairly simple device for heating rooms. When doing work, remember that the stove must not only heat, but also meet the minimum fire safety requirements.