Compost heap in an iron barrel. DIY composter made from a metal barrel

Often the first structure erected on the site allocated for construction is a toilet. Very often it is done hastily, as if temporarily, and then other, more important concerns appear, and hands do not get around to it. The toilet needs to be built immediately - permanent, hygienic, comfortable and economical.

As a rule, a toilet booth has an area of 1x1 m - this is enough for normal functioning. However, it is more rational to make it somewhat more spacious, 1.2 x 1.5 m or even 1.5 x 1.5 m. Increasing the area will make it possible to make a double toilet, as well as equip open or closed shelving for storing fertilizers, chemicals, etc. winter time the toilet booth can be used to store a collapsible greenhouse, watering hoses, equipment and other things.

For various reasons, the idea of installing a cesspool under the booth should be rejected. The cesspool will become a problem for the owner when he will have to obtain approval from the sanitary and epidemiological inspection service when registering the construction. An excellent solution would be powder-closet.

How to replace a cesspool

The function of a cesspool is performed by metal container(for example, a bucket) with a capacity of 12-15 liters. As the contents of the container are filled, a certain amount of ash, peat or sawdust is sprinkled on top from a box specially installed for this purpose. The approximate period for filling the collection tank is 10-14 days.

It is better to empty collection containers into the ground to a considerable depth (about 1 meter).

It's done like this. Using a garden drill in the ground at the border of the tree trunk circle fruit tree or at the level of its crown, a hole with a diameter of 200 mm and a depth of about 1 m is drilled. A collection container is emptied into this hole and again filled with excavated soil. It is as if the feces are sealed in the main soil. The next emptying can be done nearby, retreating in a circle by 20-25 cm.

Before emptying the collection container, a small amount of slowly decomposing waste can be placed in the drilled well ( broken glass, ceramics, etc.)

Building a toilet in the country

Country toilet project

Making a toilet booth is akin to building a model of a house: design (sketch), marking on the ground, foundation, lower frame, erection of walls, top frame and rafter system, roofing, flooring, door hinges, glazing, interior design and exterior decoration. All construction elements are simplified, minimized, almost toy-like, but they allow you to gain experience and practice working techniques.

The project (sketch) determines the shape, main dimensions of the toilet, as well as the initial building materials and their quantity. The appearance of the future structure is determined by the presence of one or another building material.

Usually the toilet is made of wood, but you can use asbestos-cement slab (flat slate) and even foam concrete blocks. The most common form of toilet - the “birdhouse” - is the most rational: it is technologically advanced and has a large functional volume.

If the project (sketch) has been drawn up, that is, the main dimensions have been determined, the site is marked on site: pegs are hammered in and cords are pulled to define the boundaries of the building. The rectangularity of such a small area can be set using an unfolded sheet of newspaper, and the accuracy can be checked using a tape measure, measuring the diagonals.

Below you can see a few examples drawings of country toilet projects. To view you must click on any of the images.

Drawings of country toilets

Toilet foundation

For most toilet booth designs, four concrete blocks measuring 260x330x440 mm, installed in the corners. To install them, you only need to remove the top soil layer (15-20 cm). It is important that the upper surfaces of the blocks lie in the same plane.

The plane can be checked using a level and a piece of a suitable board. Two or three layers of roofing felt are placed on top of each block for waterproofing.

The lower trim is installed on the foundation blocks. The easiest way is to make it from pieces of timber, tied “in half a tree” and tightly tied with staples (the rod of the staple is recessed into a specially hollowed-out socket on the surface of the beams). Preferable for bottom trim use an edged board (40 or 50 mm thick).

The sides of the bottom trim are made from two pieces of edged board, nailed through a spacer of the same thickness, as shown in the figure below.

In this case, grooves are naturally formed in the lower trim, into which the tenons of the enclosing walls can then be inserted. The sides of the lower trim are fastened using cap screws (diameter 8-10 mm).

Walling

Due to their small size, the walls of the toilet booth can be made in the form of panels from upholstery boards (lining). Sections of upholstery boards of a given size are stuffed onto two planed frame boards, which have the same thickness as the bottom trim boards. The front shield is stuffed onto three boards so that you can frame the doorway.

To give rigidity to the panels, a strut must be inserted between the frame boards. The pictures below show the front, rear and side shields. The parts of the frame boards protruding from the bottom of the boards are spikes, which, when installing the booth, are inserted into the grooves of the lower frame.

Installation of walls consists of sequential installation of panels into the grooves of the lower trim and fastening the frame boards of adjacent panels using wood grouse screws (3-4 pieces per corner). In essence, these cap screws perform the function of the upper frame, as they impart the necessary rigidity to the entire structure.

Country toilet roof

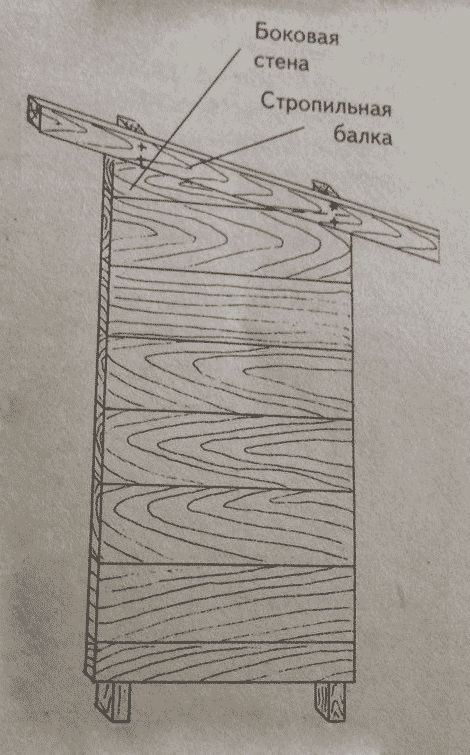

The rafter system is just two boards embedded in top part side shields (picture below).

The sheathing is placed on these two boards, which is best made of solid clapboard face down. In this case, there is no need to hem the ceiling and roof overhangs.

A reliable and simple roof is made from two layers of roofing material. Ruberoid is attached to the sheathing

felt buttons with a frequency of 15-20 cm.

Flooring

The floor is laid from edged boards 50 mm thick. The front and side surfaces of the floorboards are cleanly trimmed and nailed to the inner boards of the bottom frame with gaps (slots) of 5-10 mm. The gaps will facilitate ventilation, as well as drying the floor after wet cleaning.

Door hardware

The door to the toilet consists of a frame with a strut and trim. The strut cuts diagonally across the frame extending from top corner the porch to the bottom loop. The cladding is made of lining placed vertically. It is advisable to equip the door with a rim lock for locking at the end of the season.

Toilet container

The collection container is placed in the frame shown in the figure below.

The frame is made of bars with a cross-section of 40×40 mm or 50×50 mm. In the frame, the front wall is completely covered with clapboard, and the upper wall, in which a hole is cut, is made entirely removable. In this form, this structure is most convenient for hygienic cleaning (washing and frying in the sun). The removable top cover allows you to conveniently attach a simple “apron” (a piece of vinyl chloride film). In the powder closet booth there should be another box or other container with peat, ash or sawdust.

Flat slate toilet

toilet from flat slate

Wood, of course, is the most affordable and technologically advanced material, but if for other buildings (garage, outbuilding) it is planned to use an asbestos-cement slab (flat slate), then it is also suitable for a toilet booth.

To work with asbestos cement slab you will need a cutting machine electric machine(grinder) equipped with a stone abrasive or diamond cutting disc. Asbestos cement sheets 8-10 mm thick are cut to form the front, back and both side walls toilet booths (similar to picture 2 above). These walls are assembled with screws using frame boards, and then installation is carried out in the same way as described above. In this case, the door leaf is also made from an asbestos cement sheet mounted on a wooden frame, which is used for inserting hinges, locks and other mounting devices.

For convenience and safety of using products made from asbestos cement sheets, it is advisable to cover them with film-forming compounds (varnish, drying oil, paint, etc.).

Video

DIY country toilet

DIY country toilet and shower

Do-it-yourself toilet in the country: powder-closet without a cesspool

One of the important structures on this site or territory of a private house is a bathhouse. This is a place where you can relax and unwind, invite friends to take a steam bath. The quality of the structure’s operation depends on the correct construction of not only the bathhouse itself, but also the sewage system for it.

There are many projects for building a bathhouse that say nothing about arranging a sewer system, so the question arises whether a drainage pit is needed for a bathhouse or not.

A bathhouse is a utility building that requires water to function. In addition, water is used to restore order here. The waste generated needs to go somewhere. If they are thrown onto the site, they will soon saturate the soil so much that an unpleasant, stagnant odor will appear, and fungi and mold will begin to form under the floor. This trouble can be prevented if there is a drainage hole under the bathhouse.

When calculating the size of a cesspool for a bathhouse, as well as a sewer system for a home, many factors must be taken into account in order to ensure maximum productivity of the structure. First you need to draw up a design for a sewage pit, choose what type it will be, and calculate the volume. In particular, you should pay attention to the following parameters:

- who will use the bathhouse and how often;

- characteristics of the soil where the drainage pit will be located.

Calculation of cesspool volume

If there are many users, a larger cesspool is required. Sandy soils are better able to absorb liquids, so in this case you can build a small waste pit. But on loams and clay, water leaves very slowly, here it is necessary additional area absorption.

In areas where the soil is stable, there is no need to additionally strengthen the walls. But where the soil is crumbling, care should be taken to ensure that the hole does not fill up. Errors during the construction of a cesspool will affect the quality and durability of its functioning, so you should take into account all the nuances when carrying out work in order to avoid troubles during operation.

Since mostly water will accumulate in the cesspool under the bathhouse, and they will not be steaming there constantly, there is no need to install complex design, a regular cesspool in a bathhouse can handle waste collection and recycling.

Necessary materials

In the process of building a cesspool, you will need tools and materials that are probably in the home owner’s garage or in the summer resident’s arsenal. Depending on what structure will be installed, the materials are selected. If the site has good soil, does not crumble, and absorbs water, additional strengthening of the walls and bottom is not required. However, such conditions are very rare. In most cases, it is necessary to ensure that during operation the cesspool under the bathhouse does not fill up or become clogged with earth crumbling from the walls.

Bottom drain hole

A drainage pad should be placed at the bottom of the drainage pit to more thoroughly clean waste from the pit. Crushed stone and sand are often used for this. The following materials are excellent for strengthening walls:

- brick;

- slate;

- reinforced concrete rings;

- tires;

- metal barrels;

- plastic tanks.

The most optimal and economical option is to use improvised materials, that is, those that are at the owner’s disposal. These could be used tires from a car (large), bricks left after dismantling some utility structures, metal barrels that were once used for economic purposes.

Land works

In the process of arranging a sewer system for a bathhouse, the first stage will be earthworks. To do this, you can use special equipment, or you can dig a trench with your own hands. The second stage is much more labor-intensive, but economical. Using the equipment requires access to a bathhouse.

Land works

After excavation work, soil remained on the site. If you leave it like that, it will ruin the aesthetics of the site. It is necessary not only to dispose of it, but to use it usefully. This soil is often used to sprinkle garden beds if the soil is of good quality. If not, you can simply dispose of the soil.

A drainage hole for a bathhouse with your own hands will not be complete if you do not provide a drainage layer, which is laid after digging a pit. The bottom of the cesspool for a bathhouse must be made waterproof, and the walls will be responsible for collecting liquid from the container. Sprinkle the bottom with a mixture of sand and crushed stone. Well, if you have construction waste, they will also work great. The drainage layer must be at least 20 cm.

Construction of a cesspool

Upon completion of the excavation work, you need to lay a drain pipe in the trench and begin finishing the walls and roof of the cesspool. The scope of work will depend on what material is used. The simplest solution is to use a large plastic or metal barrel. You can find an unnecessary container at home, or you can buy a special tank at a hardware store, from which a cesspool for a bathhouse is made.

From slate

Sewerage for a bathhouse can be made using wave slate, which remained after dismantling old roof. This method is great for areas with sandy soil. The work process is simple. First, the first sheet should be laid on the bottom of the pit, then each subsequent sheet should be placed so that its edges are in contact with the edges of the previous sheet.

Construction of a slate cesspool

You can fill the space and create additional drainage by filling the container with broken slate.

From tires

Car tires can also be used to create a cesspool for a bathhouse. Due to the fact that solid waste will not flow into this sewer tank, the design can be extremely simple. Used car tires will probably be found in the garage.

Construction of a tire cesspool

The construction process will consist of the following stages:

- using a grinder you need to cut off the sides of the tires;

- carefully place the tires in the pit on top of each other;

- fill the bottom of the cesspool with crushed stone;

- make a hole for the drain pipe;

- Place a sheet of metal on top and lightly sprinkle it with soil.

Made of brick

Brick has a number of advantages, so it is used quite often to build a cesspool for a bathhouse. The material is not cheap, so you shouldn't buy it. If there is no old brick remaining after dismantling the building, it is better to use another option for constructing a sewer system. The advantage of brick is that it is not at all afraid of water, low or high temperature, resistant to chemicals and microorganisms living in the soil. The disadvantages of the material are that it is not easy to work with, and the price is too high to buy new brick for the construction of a cesspool for a bathhouse.

Probably, the vast majority of owners of dacha plots and private country houses cannot imagine their lives without their own, since such a structure is an integral part of ancient Russian traditions. A bathhouse is not only a place for washing, but also a kind of home “dispensary” that works to restore the strength and health of the owners, and provide the necessary periodic relaxation. But in order for it to bring only pleasant sensations, its arrangement, and in particular all the necessary communications, must be carried out according to all the rules.

One of the traditionally problematic components of the bath system is the disposal of used water, so it is very important to properly organize its drainage and collection site. Disposing of contaminated, untreated wastewater onto the ground or into natural bodies of water is strictly prohibited, and such an approach will inevitably lead to penalties from supervisory environmental authorities. Therefore, in the absence of a centralized sewerage system (as is most often the case), a special storage or drainage pit is usually created for these purposes. And in order for the drainage pit for a bathhouse to function effectively, it is necessary to study its design before starting construction, and during the period of arrangement work, follow the recommendations of experienced craftsmen.

Main types of drain pits

Construction of any drainage pit is a rather labor-intensive process, since the pit will most likely have to be dug manually. At the same time, such a hydraulic structure is not very complex in design, so any owner of the site can build and equip it independently, without even involving assistants, of course, if there is enough strength for excavation work.

Drainage pits can be divided into three main types - a sealed container, a pit with drainage capacity, and one consisting of several chambers.

First, let’s figure out what each of the varieties is, in principle.

- A sealed drainage pit is most often installed on construction sites with shallow groundwater aquifers. It is more often called a cesspool, that is, requiring periodic emptying of accumulated volumes of dirty water.

To build it, a pit is dug into which a container with a sufficiently large volume is installed. This is where wastewater will be collected. As the container is filled to a certain critical level, the waste is pumped out by a sewage disposal machine.

This option is environmentally friendly, since no contaminants or chemical cleaning solutions get into the soil and groundwater at all, which can negatively affect the condition of the fertile soil on the site, as well as have negative impact to high ground aquifers. However, this option is not convenient and economical, since you will have to constantly monitor the filling level of the container and often call specialized vehicles, and such services are not cheap.

Prices for septic tanks

- There is no hermetically sealed bottom created in the drainage drainage pit. It is used as a bulk layer of filtering building material - most often crushed stone or gravel is chosen for this purpose.

In addition, often in the walls drainage pit At a certain height, holes are also made through which water will be absorbed into the soil. This option is perfect for a bathhouse and is perhaps the easiest to build, however, if the soil characteristics on the site allow it.

- A septic tank is a whole system consisting of two or more chambers that have different purposes.

In any of the options, the first chamber most often has a sealed design and is used for collecting, primary filtration and purification of waste - solid components settle to the bottom, and liquid ones are clarified and undergo a cycle biological treatment due to the action of aerobic microorganisms. This container is connected to the second chamber with a special overflow pipe - clarified liquid waste flows into the next compartment, which is already organized according to the principle of a drainage well. Water passes through the drainage, is further purified and absorbed into the soil.

If a septic tank of three containers is planned, then the third chamber is made into a drainage chamber. The second serves for the final sedimentation of suspensions, deeper purification of water due to the action of anaerobic microorganisms. And from here the purified liquid is poured into the drainage well.

A septic tank is most often installed when it is expected to collect the entire considerable volume of liquid waste from both a residential building and a bathhouse.

What is important to know about the design and rules of septic tank equipment?

A septic tank is already quite complex engineering structure, the creation of which must obey certain rules. Often home owners prefer to install finished system factory production. What are the rules for setting up such a treatment plant, and what to look for? Special attention when - read in the special publication of our portal.

Materials for arranging a drainage pit for a bathhouse

Various materials can be used to construct bath drainage pits. Their choice directly depends on the expected volume of wastewater, the financial capabilities of the site owners and the convenience of construction.

Barrel drainage pit

To create this water drainage system, metal or plastic barrels of different sizes are used. However, such a drain can be arranged in different ways:

- First option. At the bottom of the excavated pit, covered with drainage material 300–400 mm thick - crushed stone or coarse gravel, after compaction, a barrel with perforated walls and a cut bottom is installed. In this case, it is taken into account that between the walls of the barrel and the pit there should be a space of at least 100 mm, which is also filled with drainage backfill.

A pipe is inserted into the barrel at the required slope angle, through which used water from the bathhouse will flow into the container. These drains will gradually seep into the drainage layer through holes in the walls and through the bottom, be cleaned, and then be absorbed into the surrounding soil. In some cases, drainage material fills not only the free space of the pit, but even the barrel itself, that is, water will flow directly into the drainage layers and then into the ground. This way the barrel will never fill up.

It must be correctly understood that such a scheme is not suitable for collecting other types of wastewater from a residential building. For a bathhouse that is used for its intended purpose once or twice a week, such a pit becomes one of the most optimal options.

- Second option. In this method of arranging a pit, two barrels are used, installed at different levels - one above the other by about 200 mm. They are connected to each other at the top by an overflow pipe. Water from the bathhouse enters the first upper container, soap sediment and solid suspensions settle in it, and when it is filled, the water is poured into the second barrel, to which one or two long drainage pipes with perforated walls are connected.

Outlet pipes from the second tank are laid in drainage trenches filled with gravel or crushed stone, through which water purified from chemical precipitation will be distributed, moistening the soil. The trenches are filled from above with a layer of fertile soil, approximately 500 mm deep, and can be planted ornamental shrubs that will receive constant watering. Thus, two problems are solved at once - draining water from the bathhouse and irrigating plants on the site.

This option for arranging a drainage pit will be discussed in detail below.

Brick drain pit

The walls of the drainage pit can be arranged using bricks, which are laid out with gaps - through them, water is drained into the drainage backfill and further into the ground. The difference between this pit and the first version, made from a barrel, differs only in the material, but the operating principle remains the same. In the gap between the ground and brick walls a drainage layer is filled in, which will purify the water and distribute it throughout the pit, discharging it into the ground.

A pit made of brick is more durable and is designed to hold a larger volume of water. Moreover, if you dig a pit deep enough, and the bottom and lower part of the walls are sealed, then this structure can also be used to drain other waste, but in this case the pit will have to be cleaned periodically.

To build this version of a drainage pit, it is not at all necessary to use new brick - used material is also quite suitable.

Prices for metal barrels

metal barrels

Drainage pit made of concrete rings

If financial and technical capabilities are available, then a drainage pit can be built from perforated concrete rings, which are installed in a prepared pit. After installing the rings, a drainage backfill is arranged at the bottom of such a well.

In this option, the entire space between the walls, as in previous cases, is also filled with drainage material, so the hole, provided it is used only for bathing needs, will never be filled with water. In the same case, when the pit is deep enough and the bottom of the well is cemented, then such a pit is suitable not only for a bathhouse, but also for a general one. True, this will require additional calculations, assessment of the absorbent properties of adjacent soils and the location of aquifers.

Pit made from old car tires

A drainage pit made from unnecessary car tires can only be used for liquid waste, so it is ideal for collecting periodically incoming water from a bathhouse.

Tires are installed in different ways: in some cases, holes are cut out in their side walls, in others, a small gap is provided between the slopes, in others, the outer walls are almost completely cut off, but the principle of operation of the drainage pit remains the same.

This option for draining water from a bathhouse can be called the most popular, since it is simple to install, affordable (tires are easy to find for free) and practical to use.

The numbers on the diagram indicate:

1 – Crushed stone or coarse gravel – drainage backfill, in a layer 250÷300 mm thick.

2 – Old car tires.

3 – Drain pipe from the bathhouse (there may be two of them)

4 – Crossbars for laying the lid.

5 – Cover or hatch.

Around the stack of wheels laid out, and sometimes inside the resulting well, a drainage cushion is backfilled, which allows you to retain and purify the water coming from the bathhouse. With good drainage capacity of the soil and periodic use of the bathhouse, the pit never overflows.

It should be noted that other materials that can withstand the effects of high humidity are also suitable for the construction of a drainage bath pit.

How to independently equip a drainage pit for a bathhouse

Inspection of the soil at the site of the planned drainage pit

In order for the bathhouse drainage system to be effective, it is necessary to determine the type of soil in the area at the approximate depth of the planned pit. To do this, a trench or test hole is dug. In order for the bathhouse to be used in winter, the depth must be below the freezing level of the soil. Information about soil freezing in a specific area can easily be found on the Internet, or you can consult with the owners of neighboring plots who have been using similar drainage systems for a long time.

Prices for concrete rings

concrete rings

Have good drainage abilities sandy soils, sandy loam, including those with rocky inclusions.

But dense clay layers can cause problems. At high humidity, they are well saturated with water, swell, and become practically waterproof; when dry, they shrink. In addition, they are highly susceptible to frost swelling. These qualities of such soils are unfavorable both for laying and laying pipes in trenches, as they can lead to deformation and damage to themselves and other elements of the system.

Constructing a drainage hole in such soil, if it extends to great depths, is an almost pointless exercise. Well, if you have to lay a pipe through such layers to a drainage pit that reaches the depth of soil with high absorbency, then the bottom of the trench must be lined with a sand cushion 100–120 mm thick, which will prevent the harsh impact of ground vibrations on the elements of the drainage system.

The level of groundwater (GWL) is also important, since the degree of absorption of water entering the drainage pit will also directly depend on this. So, between the bottom of the pit and the location of the stable aquifer there should be a distance of about 1000 mm. If the groundwater is located close to the surface, then the contaminated water will not flow well into the drainage, and such a well will soon turn into a fetid pit, as it will be constantly filled. In this case, as with clay soils, the option of a drainage pit is not suitable. You will have to either install a sealed container that requires periodic emptying, or organize water drainage to special surface filtration fields.

Having chosen the material for constructing the pit, you need to decide on a few more important points its arrangement, on which the efficiency of the system and the environmental safety of both the site itself and its inhabitants depend.

First of all, you will need to decide on the location where the hole will be located.

- Quite often, owners place a drainage hole directly under the building, but this becomes possible only if:

- the pit is equipped before the construction itself;

— the building rises above the ground on a columnar or pile foundation, which will need to be well waterproofed;

- under the bathhouse building there must be provision good ventilation;

- the sewer pipe connecting the bathhouse drain and the pit will require effective thermal insulation.

- If the pit is located separately, away from the bathhouse, then it is necessary to ensure that it is located at the required distance from sources of drinking water, natural reservoirs, residential and outbuildings, trees, the border of the site and the road passing near it. The required standards are shown in the diagram below:

- The pit should be located below the level of the drain hole in the bathhouse floor by at least 150÷200 mm, and the recommended distance from the bathhouse building is 3÷5 meters.

- If the drainage pit has to be located fairly close to the bathhouse structure, then:

- the bottom of the pit should have a slope of 20÷25 degrees, draining water from the walls of the building;

- perforation in the walls of the barrel, concrete rings or tires must be done on the side that will be located further from the walls of the bathhouse;

- It is very important to maintain the correct slope of the sewer pipe so that dirty water does not stagnate inside the channel, but immediately goes into the drainage hole, and there is no risk of freezing when using the bathhouse in winter. It is especially necessary to remember this in cases where it is decided to place the pit quite far from the bathhouse. The amount of required slope depends on the selected pipe diameter - this is clearly shown in the diagram below:

It should be noted that to organize the drainage of water from a small bathhouse without a toilet, a pipe with a diameter of 50 mm is usually sufficient. In order to maintain the required slope, when digging a connecting trench, as well as when adding a sand “cushion” to it, you should control the difference in its depth using a building level.

Arrangement of a drainage pit - step by step

In this section of the publication, two options for drainage pits will be considered, which can be arranged independently.

Regular drainage hole

This version of the drainage pit has a design that can be made of various materials, which were discussed above.

| Illustration | |

|---|---|

| After determining the location of the drainage hole, you can proceed to digging a pit. For a bath drainage well, a pit depth of 2500÷3000 mm will be sufficient. It can have a round or square cross-section - it will depend on the chosen material for the walls. For example, if the pit is made of brick, then it is more convenient to lay a square or rectangular shape from it, but in some cases a round well can also be built from it. The diameter of the pit should be 150÷200 mm larger than the prepared container. |

| When the pit is prepared, a trench is dug from it to the bathhouse building at the required angle for laying the drainage pipe. The width of the trench can be 300÷500 mm, and the depth will depend on the level of soil freezing in the area where the bathhouse is built, but not less than 500 mm at the entrance to the well. |

| The bottom of the finished pit is filled with medium-fraction stone - gravel, crushed stone, crushed brick or even broken slate. The drainage layer must be at least 300 mm, as it is designed to retain dirty water and purify it, that is, moisture must reach the soil by capillary action, which will allow it to be quickly absorbed. |

| Further, they act differently. You can lay a sewer pipe right away, and then work on the brick walls of the water intake well, or you can first install or build a container, and as it is being built, a drainage pipe is inserted into one of the specially made holes. Most often, the pipe is laid at a time when the walls are brought out to the level of the depth of the trench, otherwise it will simply interfere with the work. |

| So, the walls of the drain well can be built of brick. The laying is carried out maintaining a clearance between adjacent bricks in a row of 40÷50 mm. The wall can have a thickness of half a brick or one brick - this parameter is chosen by the builder, and largely depends on the amount of prepared material. Having raised the walls of the well by another 200÷300 mm, the space between the soil and brick walls is filled with drainage backfill. |

| If concrete perforated rings are used to form the walls, then specialized equipment will have to be used to install them, since each of them has an impressive mass, and distortions must not be allowed during installation. After their installation, the distance between the soil and concrete also needs to be filled with drainage backfill. It should be noted here that if concrete rings are used for the pit, then you should not rush to install them in the hole of the sewer pipe wall, since under their weight they can sink somewhat into the ground - sometimes by 100-150 mm. Therefore, it is recommended to leave the finished concrete well alone for some time to shrink, otherwise the plastic pipe may crack or break due to the resulting pressure and tension. |

| When using metal barrels for a pit, the bottom and lid are cut off, and the side walls can simply be cut using a grinder. The cuts are made at a distance from each other of 200÷250 mm horizontally and in increments of 100÷120 mm in height. If two barrels are used, they are placed one on top of the other. After installing the lower one, the free space around its walls is filled with drainage. After this, in the second of them, in the top, a hole is marked and cut through which a drainage pipe will be installed into the barrel. The hole according to the markings can be cut with a grinder, but an opening made with an electric jigsaw will still be neater. To do this, a hole is drilled at one of the points on the marked circle into which the tool file should fit freely. |

| If plastic barrels are prepared for the drainage pit, then they are mounted in approximately the same way as metal ones, but quite often the drain pipe is connected through the top lid of the container. The bottom of a plastic barrel can also be cut off or several round holes with a diameter of 100÷120 mm can be cut into it. |

| Holes with a diameter of 10 mm are drilled in the side walls along the entire perimeter of the polymer container with a frequency of 100÷150 mm horizontally and vertically. Crushed stone or gravel is poured around the barrel and under it, into which, just as in previous cases, water will flow from the holes of the barrel, be cleaned and go into the ground. |

| The most commonly used material for arranging a bathhouse drainage well is car tires, which are stacked one on top of the other. WITH inside At the edges of the tires, in three or four places, holes with a diameter of 10 mm are drilled, through which they are fastened together using, for example, plastic clamps. The sewer pipe can be connected between two tires. In this case, for emphasis, along the edges plastic pipe and in three or four more places between the tires at the place where it passes, bricks are installed, which will relieve the load on the plastic from the upper slopes. |

| Another option for drilling the pipe is to install it in a hole cut in the side wall of the tire. When choosing this method, it is necessary to provide for possible shrinkage of the structure by cutting a hole larger than the diameter of the pipe by 70÷80 mm. |

| Quite often, the drainage bath pit is not filled with drainage material around the barrels or tires, but is filled with it two-thirds - this allows the water to slowly flow to the soil walls and slowly be absorbed into them. |

| It is recommended to strengthen the top of the pit with brick walls by constructing a concrete platform with a hole for a hatch. To do this, a formwork is built around the well, into which a reinforcing grid is laid, and then it is filled with concrete mortar, a layer 70–80 mm thick. |

| After the concrete has hardened, a homemade cover made of a steel sheet and a corner is installed on the hole. Factory-made hatches, metal or plastic, are also quite applicable. |

| Special plastic sewer manholes may have various shapes and linear parameters. So, when planning to install this particular option, the hatch is purchased in advance, and the top cover of the drainage pit is built according to its dimensions. |

| Well from concrete rings usually covered with a special lid made of the same material with a ready-made hole for a plastic or cast iron hatch. |

| Well walls built from tires or barrels have less rigidity than brick or concrete, so it is best to strengthen them with cement mortar mixed with crushed stone. If the drainage was filled between the walls of the well and the soil, then its top layer, 120÷150 mm high, is recommended to be made from the solution mentioned above. Further, the top of the pit can be left in this state by simply installing a hatch on the hole, or a concrete platform can be built over the structure and then backfilled with soil. |

A pit based on the principle of a two-chamber septic tank with access to a filtration field

The second option is more complex in design, but its functionality is significantly higher. This system is perfect for installation in areas with groundwater located close to the surface, since it does not require a deep pit. In addition, such a design can also be a solution for organizing drainage of water from the foundation, from a storm well, filled from linear rainwater inlets on the site or their gutters on the eaves of the roof of the house.

To figure out how to cope with the arrangement of such hydraulic structure, this process should be considered in detail.

| Illustration | Brief description of the operations performed |

|---|---|

| This system uses two plastic barrels, which are easy to prepare for installation work and connect to sewer pipes made of the same material. Usually, for the drainage pit of a small bathhouse, two or three containers with a volume of 200÷250 liters are enough. |

| The pit for installing barrels is also dug 100÷150 mm larger than their diameter, and due to the fact that containers of equal size will be installed at different levels, the pit for them should have a stepped configuration. The depth of the pit in this system should be more height barrels 450÷500 mm. This distance will be needed to create a drainage cushion under the barrel and a recess for the pipe entering it. The difference in the installation level of the containers should be 150÷200 mm, and the distance between them varies between 200 and 300 mm. The barrels are installed in one line. The bottom of the pit is compacted and filled with medium-fraction crushed stone, a layer 80÷100 mm thick, which also needs to be compacted. |

| Next, you can move on to working on preparing the containers. The barrel installed above will serve as the primary chamber, that is, a sump for dirty water. A neat hole is cut in its top cover into which the drain pipe will be installed. In the side wall, on the opposite side from the hole in the lid, holes are cut for a pipe that will connect the first barrel with the second, installed slightly lower. To insert plastic pipes into the lid or into the walls of the barrel, you can find special flanges at a plumbing store, such as the one shown in the illustration. |

| If not, then you will have to cut the hole with maximum precision, and then to seal it, use high-quality silicone sealant. |

| Additionally, it is recommended to cut a hole for installing a ventilation pipe with a diameter of 40÷50 mm, or install a tee, as shown in the illustration, where one outlet will be intended for connecting the sewer drain pipe from the bathhouse, and the other, vertical, for the ventilation pipe. |

| The second barrel is equipped with three holes, one of which is drilled in the top lid, and two in the side wall, 100÷120 mm below the top edge. The axes of these side windows should be radially rotated from the axis of the central hole by 45 degrees. |

| Nozzles with 45-degree bends installed on them are cut into the side holes and sealed. As a result, the pipes for connecting the drainage pipes will become parallel to each other - as shown in the illustration. |

| Additionally, in the lower part of the walls of the installed second barrel, on the opposite side from the entrance, small holes with a diameter of 5 mm are drilled, at a distance of 150÷170 mm from each other. This is an additional outlet of water into the drainage fill around the barrel. However, if powerful filter fields will certainly cope with their task, and even more so if such a septic tank has to be installed in the immediate vicinity of a bathhouse, then this operation is not necessary. |

| The result should be a design similar to that shown in the illustration. Having installed a system of barrels and pipes, you can proceed to creating a filtration drainage field. |

| For the drainage area, which is located at a slope from the installed barrels, a trench is dug, having a width of 1200÷1500 mm and the same depth to which the first barrel standing above is buried. If desired, the drainage filter field can be extended over the entire area, since it will not interfere with the arrangement of beds for annual crops or for planting shrubs above it. A geotextile fabric is laid at the bottom of the resulting channel, on top of which drainage will be laid. Filling the trench with crushed stone is done in layers, each of which should be carefully compacted and distributed at a slope along pre-set pegs. The slope of the trench should be approximately 25 mm per linear meter. Pegs installed in advance with the required height difference will become a kind of beacons for the correct filling of the drainage layer. |

| As drainage material is poured around the lower barrel, water is poured into it, otherwise external soil pressure may deform it. It is recommended to fill the space between the walls of the barrels with gravel or coarse sand, which should be compacted by pouring water. Next, pipes with perforated walls are connected to the nozzles, through which water will be distributed throughout the drainage area. Holes are drilled in increments of 150÷180 mm along the bottom and sides of the pipes. After drilling, the pipes are dressed in a filtering “casing” made of geotextile - so that the inside of the pipes is not subject to silting. |

| The next step is to fill the pipes and the entire trench space with medium-fraction crushed stone mixed with sand. Such a layer should reach the lid of the barrel installed below, that is, completely cover the pipes from above with a layer of at least 100–120 mm. It is best to backfill several different layers of soil on top of the crushed stone. So, the crushed stone is first covered with geotextiles, on which a layer of moistened sand 70÷80 mm thick is laid, and the rest of the space can be filled with fertile soil. On this site it is quite possible to arrange a flower bed, plant annual vegetable crops or even small shrubs with a shallow fibrous root system. |

At the end of the publication, it should be noted that there are other materials that can sometimes be found in the yard among old supplies or even seemingly unnecessary trash, which in fact may well be suitable for building a drainage pit for a bathhouse. For example, you can find use for old sheets of corrugated or smooth slate, or even those left over after roofing works covering scraps of corrugated board.

Some resourceful owners country houses line the walls of the drainage well with glass or plastic bottles, which are filled with sand, find others very interesting solutions. Therefore, if you want to save money, and at the same time free up part of the yard or barn room from old materials, then you need to use your imagination “to the fullest” - and act! We will be glad if any creative master shares his innovations on the pages of our portal.

Another example of a simple drain for a bathhouse is shown in the video below.

Video: How to make a bath drain yourself at minimal cost

Always requires the organization of a device for draining water. It is necessary to take care of the drain even before its construction begins. The drainage pit is the basis of the entire drainage system. The option of draining water with a drainage pit is very popular among summer residents. If there is a sewer line or ditch not far from the summer cottage, then making a hole will become impractical. In such cases, it makes sense to run drainage pipes to the sewer system and or ditch. It is strongly not recommended to make a drainage hole in areas of land with a high groundwater level, as this will not lead to any benefit, and the efforts will be wasted. Therefore, before you start building the bathhouse itself, there is no need to rush into preparing the drainage pit. If a drainage hole is still needed, then we begin construction.

So where to start? Like any other building - from design. Specialists in the field of engineering are not required here, but you need to make a few calculations. Answer the questions:

- How many people will visit the bathhouse?

- What are the characteristics of the land on the site?

- How high is the groundwater level?

It has already been said that when the groundwater level is high, it is better not to make a drainage hole. But how do you measure the level itself? The most accurate method is drilling a well. But not everyone has a drilling rig lying around in their garage. Take a closer look at areas where vegetation is not watered. If moisture-loving plants grow there, then there is definitely water in the soil. The vegetation is dense, which means the hole needs to be dug deeper. The volume of the cesspool will depend on how intensively the owners use the bathhouse. The more people are expected to visit the steam room and shower, the larger the volume of the pit will be required. If there is a deficiency, waste water may end up overflowing. Is the soil loose? Then you will need to strengthen its edges. If the soil is hard, then it’s a plus for time.

Having determined all the characteristics of the land and the “productivity” of the future bathhouse, you can choose a place for the pit. Bathhouse construction experts advise digging a hole two meters from the walls of the bathhouse itself. Too far - then the required slope will not be provided and the water will stagnate.

Materials required for construction

If the soil is dense and well-absorbing, a lot of starting materials will not be required. In this case, there is no need to strengthen the walls of the pit. The bottom can be filled with crushed stone and rack sand. However, cases with such ideal land are not common in our country. In the vast majority of cases, the walls of the pit have to be strengthened, otherwise it may crumble. Brickwork, slate or similar material works well for this. Another option: a plastic or metal barrel with a cut out bottom, in the lower part of the walls of which you will need to make several holes so that the drain water is filtered through the ground.

An advantageous pit shape option is a cylinder. A pit made in this form distributes the load on the soil evenly, reducing the risk of structural failure to a minimum. The cube-shaped camera is inferior in this regard.

Trench preparation and excavation work

Where to put the excavated soil? If the soil is of good quality, sprinkle it on an area with vegetation. Stones, sand and clay for removal. We decided to equip a pit brickwork, ceramic bricks- that's it. Durable material that does not have “hydrophobia”. You can save on bricks by laying bricks edge up. You need to leave holes between the ends - this is an outlet for water. Simple and helpful advice– using natural stone, so as not to spend money on brick, is beneficial.

Is the masonry complete? Then we begin to form the bottom, a waterproof bottom! The same crushed stone and sand will serve as backfill. Construction waste is also suitable. It is better not to underestimate the bedding layer, at least 20 cm. The upper part of the masonry should exceed the ground level by 30-40 cm. Cover the pit concrete slab or metal sheet.

If vehicles will pass along the site above the pit, then the thickness of the slab should be at least 30 cm. In case the soil does not absorb well drain water, then you can leave holes in the slab so that when the pit overflows, you can pump out the wastewater. Only this hole needs to be covered with something, otherwise you can accidentally fall into it. The strengthening is completed, all that remains is to fill its outer part with already dug soil (fill the unusable part of the hole with sand). In the place of the former pit, you can grow plants or create a passage.

Pit made from old tires

As a rule, the drains do not contain solid waste, which means that the arrangement options can be very simple. Special materials may not be required at all. Improvised means will also do. Used car tires are perfect for this. The larger the tire diameter, the better. The sidewalls of old tires need to be cut off using a grinder or jigsaw. So, the prepared tires are placed on top of each other in the pit. The lower part of the pit is also filled with crushed stone. In the tire lying on top you need to make a hole for the drain pipe and adapt it. After this, you need to put a metal sheet on the cylinders and fill it with earth according to the level.

Drainage hole made using slate

Wave slate is perfect for filling a drainage hole. The first sheet is placed on the bottom. The second is superimposed on the first so that their waves touch each other high points. Subsequent sheets are also laid until 30-40 cm remains to the top of the pit. The drain pipe is inserted into the gap of the upper quarter of the slate masonry. You can strengthen the structure by filling broken pieces of slate, and then filling the remaining empty space with soil. This method is mostly suitable for sandy soil.

The last two methods should not be used if it is expected that vehicles will pass through the hole.

We have already written about the construction of cesspools using tires, concrete rings and barrels, today we will write to you about how to build sewer well from asbestos slate. We will talk about using flat slate, but this does not mean that this task cannot be handled using wavy slate.

What materials are needed to build a well?

In order to build a well you will need the following:

Flat slate sheets;

steel pipes;

steel wire;

corners;

shovel;

Bulgarian;

welding machine;

roulette, building level;

cart.

Note that in the same way you can arrange a pit for a country toilet, but that’s just us, by the way.

How to build a cesspool using slate

Dig a hole. As you probably already guessed, the pit should be rectangular, preferably square. To develop the soil you will need a shovel and a cart, as well as buckets. As for the depth of the hole, it's up to you to decide.

When the pit is ready, begin organizing the metal frame. You need to weld a frame made of steel corners under the bottom of the pit. You will need two such frames. Afterwards, one of them must be laid at the bottom of the pit. The pipes must be welded at the corners of the lower frame, and then at the corners of the upper one. As a result, you will get a rectangular frame.

At the next stage, you need to start arranging the walls of the well. Everything is simple here. The task is to cut required amount pieces of flat slate, then lower it into the hole, sewing up all sides of the rectangular frame. Self-tapping screws can be used to secure the slate.

When ready, the space between the slate and the walls of the pit must be filled with soil and then compacted. Well, only then you need to make a lid. If the hole was made for installing a toilet, you need to start installing it.

www.raznyesamodelki.ru

Practical fencing

Until recently, slate was the most common roofing material with big amount operational benefits. Today its popularity has fallen slightly; more modern materials have appeared on the market: bitumen shingles and metal tiles. It’s a pity to throw away the old covering, which is why many people have warehouses of old slate sheets in their dachas. It’s a shame to throw it away, and there’s no need to do it.

You can easily assemble and make a temporary toilet, Summer shower from sheets of slate, you can build fences from it, covering with it a fence made from a chain-link mesh, for example. This solution will protect the garden plot from the prying eyes of passers-by and the penetration of neighboring dogs.

A standard slate sheet has a length of 175 cm, the sheet is cut in half and simply, with an overlap on the chain-link, is dug into the ground with its lower edge to a depth of 40 cm. If the soil is thoroughly compacted after this, no additional fastenings are needed to stabilize the fence. If desired, slate can be easily painted by choosing the right color; it is not difficult to easily integrate it into the style of your site.

Note! Such a partition can protect a personal plot from the spread of weeds, which with their roots try to gain a foothold on the edge of the neighbor’s plot.

Shelves in the cellar

Another way to use old slate was suggested by experienced summer residents and gardeners. To store supplies, they propose to build comfortable and durable shelves using slate, allowing you to organize a convenient storage system for existing supplies. The shelves are constructed as follows:

- In the corners of the pantry, brick racks are laid, the length of which should match the width of the slate sheet. The height of the racks is 90 cm.

- A sheet of slate is laid on the racks.

- Formwork is constructed around it.

- Reinforcement pipes are laid into the slate ribs.

- The solution is mixed as for a cement screed.

- A sheet of slate is poured with it; the layer of mortar should be 10 cm.

- The result should be monolithic concrete - a fairly strong, spacious shelf that can easily accommodate any container for storing vegetables and fruits.

If the cellar is large, such shelves can be placed around the perimeter, made short or long. Many will think that using boards in this case is easier than slate, but the use of the described material, as practice shows, helps to save significantly. In addition, the slate does not need to be removed from the formwork. It can be painted or whitewashed with lime. Then the shelves will look quite neat.

Slate beds

If you have a vegetable garden at your dacha, it’s easy to assemble neat garden beds using slate. It's easy to make them yourself. Look at the photo to see how decorative a garden like this looks. The use of slate has quite practical purposes. Such structures help to keep the soil within one bed.

Such a partition is a reliable barrier to rodents and the spread of weeds. The slate laying process itself consists of several stages:

- First the slate needs to be cut. This can be done along the plates or across the waves, as shown in the photo.

- Then the boundaries of the bed are outlined.

- Trenches are dug along the entire perimeter. Their depth should be half of the prepared fencing product.

- Slate blanks are placed in the prepared trenches.

- All that remains is to dig the trenches and compact the soil around the installed sheet parts.

- In order to give the walls of the bed greater stability, metal pegs are buried in the ground.

Note! The installation of the described fence has certain nuances. If the waves in the beds are located horizontally, plant shoots and their roots can easily grow along the depressions.

Any digging of the earth in this case will lead to the death of the plant. Vertically located waves will not become an obstacle to weeding the beds.

It is best to cut slate with a grinder. Experienced craftsmen When performing such work, the angle grinder is directed in the direction opposite to the wind direction. In this case, the dust will be blown away from the cutting person. Since asbestos dust is dangerous to humans, it is necessary to protect yourself from it while working by wearing safety glasses over your eyes and covering your nose with a gauze bandage. Do not use a wood saw to cut slate. This is a traumatic job; one wrong move can cause you to lose your arm.

Pros of using slate fencing

Experienced gardeners today not only make beds from slate sheets, they use it to assemble flower beds and lay slate in greenhouses. A garden path covered with flat sheets is durable and reliable. Practicality and decorativeness are not the only advantages of such a solution.

- Slate is a material that quickly heats up in the sun, heats up and easily transfers excess heat to the soil. This has a beneficial effect on the growth of any plant.

- A fencing for a garden bed assembled using asbestos-cement sheets is difficult to destroy.

- In the future, there is no need to carry out any other work with such a fence. Set it and forget it for a long time.

- By using old slate sheets, there is no need to spend money on purchasing wooden beams.

- If desired, the sheets can be easily painted in any color; painting increases the decorative properties of the fence.

If you want to repeat a similar experiment in your garden, it is useful to study in advance the disadvantages of asbestos-cement products. On hot summer days, such a fence will contribute to overheating of the soil, so the plants will need to be watered more often. In places where long rains are common, the soil under the fence is often washed away, so they constantly tilt. This forces the garden owner to constantly straighten the fence. For many, this procedure will seem tedious.

Foundation and cesspool for toilet

Old slate sheets are often used to construct formwork for pouring foundations for outbuildings. In this case, after the concrete has hardened, the formwork does not need to be removed.

Since on personal plot Often there is no central sewerage system; the toilet and utilities serving the kitchen and bathroom cannot function without a cesspool. In this case, slate is used to strengthen its walls. The sheets are cut to the size of the pit walls and simply go down. To prevent the sheets from falling, they are fastened together with reinforcement corners. Next, reinforcement bars are placed in the gaps between the pit and the slate sheets. The cracks are filled with cement mortar. In order for the walls of the cesspool to withstand the pressure, they are pushed apart with wooden blocks, as shown in the photo.

After the concrete has dried, the cesspool for the toilet is ready.

Disputes about the dangers of slate

Many, after reading the article, will put forward a lot of arguments in favor of refusing to use the material described. But experts are rushing to reassure everyone. The described material is made from a mixture of three ingredients: Portland cement, asbestos fiber and water. The first two components are completely safe for human health. But asbestos fiber can cause suspicion.

There are several varieties of this material; two are used in slate production:

- amphibole-asbestos (natural base);

- chrysotile asbestos (a derivative of the serpentine group).

European scientists conducted research and found that the first type of slate can be considered dangerous for humans. In Russia, amphibole asbestos is not used for the production of roofing material. Therefore, for those who are afraid for their health, experts recommend purchasing slate from domestic brands. You can easily use it in your garden without any fear.

As you can see, the use of old slate helps solve purely practical problems on a household plot. You can make a temporary toilet, an outdoor shower, assemble a greenhouse or any kind of fencing using waste.

How to make a chest with your own hands

How to make a box with your own hands

How to choose a tent for a summer residence

DIY gas cylinder grill

montazhnik02.ru

How to replace a cesspool

The function of a cesspool is performed by a metal container (for example, a bucket) with a capacity of 12-15 liters. As the contents of the container are filled, a certain amount of ash, peat or sawdust is sprinkled on top from a box specially installed for this purpose. The approximate period for filling the collection tank is 10-14 days.

It is better to empty collection containers into the ground to a considerable depth (about 1 meter).

It's done like this. Using a garden drill, a hole with a diameter of 200 mm and a depth of about 1 m is drilled into the ground at the border of the trunk circle of a fruit tree or at the level of its crown. A collection container is emptied into this hole and again filled with excavated soil. It is as if the feces are sealed in the main soil. The next emptying can be done nearby, retreating in a circle by 20-25 cm.

Before emptying the collection container, a small amount of slowly decomposing waste (broken glass, ceramics, etc.) can be placed in the drilled well.

Building a toilet in the country

Country toilet project

Making a toilet booth is akin to building a model of a house: design (sketch), marking on the ground, foundation, lower frame, erection of walls, top frame and rafter system, roofing, flooring, door hanging, glazing, interior design and exterior decoration. All construction elements are simplified, minimized, almost toy-like, but they allow you to gain experience and practice working techniques.

The project (sketch) determines the shape, main dimensions of the toilet, as well as the initial building materials and their quantity. The appearance of the future structure is determined by the presence of one or another building material.

Usually the toilet is made of wood, but you can use asbestos-cement slab (flat slate) and even foam concrete blocks. The most common form of toilet - the “birdhouse” - is the most rational: it is technologically advanced and has a large functional volume.

If the project (sketch) has been drawn up, that is, the main dimensions have been determined, the site is marked on site: pegs are hammered in and cords are pulled to define the boundaries of the building. The rectangularity of such a small area can be set using an unfolded sheet of newspaper, and the accuracy can be checked using a tape measure, measuring the diagonals.

Below you can see a few examples drawings of country toilet projects. To view you must click on any of the images.

Drawings of country toilets

Toilet foundation

For most toilet stall designs, four concrete blocks measuring 260x330x440 mm installed in the corners are suitable as a foundation. To install them, you only need to remove the top soil layer (15-20 cm). It is important that the upper surfaces of the blocks lie in the same plane.

The plane can be checked using a level and a piece of a suitable board. Two or three layers of roofing felt are placed on top of each block for waterproofing.

The lower trim is installed on the foundation blocks. The easiest way is to make it from pieces of timber, tied “in half a tree” and tightly tied with staples (the rod of the staple is recessed into a specially hollowed-out socket on the surface of the beams). It is preferable to use an edged board (40 or 50 mm thick) for the bottom trim.

The sides of the bottom trim are made from two pieces of edged board, nailed through a spacer of the same thickness, as shown in the figure below.

In this case, grooves are naturally formed in the lower trim, into which the tenons of the enclosing walls can then be inserted. The sides of the lower trim are fastened using cap screws (diameter 8-10 mm).

Walling

Due to their small size, the walls of the toilet booth can be made in the form of panels from upholstery boards (lining). Sections of upholstery boards of a given size are stuffed onto two planed frame boards, which have the same thickness as the bottom trim boards. The front shield is stuffed onto three boards so that you can frame the doorway.

To give rigidity to the panels, a strut must be inserted between the frame boards. The pictures below show the front, rear and side shields. The parts of the frame boards protruding from the bottom of the boards are spikes, which, when installing the booth, are inserted into the grooves of the lower frame.

Installation of walls consists of sequential installation of panels into the grooves of the lower trim and fastening the frame boards of adjacent panels using wood grouse screws (3-4 pieces per corner). In essence, these cap screws perform the function of the upper frame, as they impart the necessary rigidity to the entire structure.

Country toilet roof

The rafter system is just two boards embedded in the upper part of the side panels (picture below).

The sheathing is placed on these two boards, which is best made of solid clapboard face down. In this case, there is no need to hem the ceiling and roof overhangs.

A reliable and simple roof is made from two layers of roofing material. Ruberoid is attached to the sheathing

felt buttons with a frequency of 15-20 cm.

Flooring

The floor is laid from edged boards 50 mm thick. The front and side surfaces of the floorboards are cleanly trimmed and nailed to the inner boards of the bottom frame with gaps (slots) of 5-10 mm. The gaps will facilitate ventilation, as well as drying the floor after wet cleaning.

Door hardware

The door to the toilet consists of a frame with a strut and trim. The brace cuts diagonally across the frame, running from the top corner of the narthex to the bottom hinge. The cladding is made of lining placed vertically. It is advisable to equip the door with a rim lock for locking at the end of the season.

Toilet container

The collection container is placed in the frame shown in the figure below.

The frame is made of bars with a cross-section of 40×40 mm or 50×50 mm. In the frame, the front wall is completely covered with clapboard, and the upper wall, in which a hole is cut, is made entirely removable. In this form, this structure is most convenient for hygienic cleaning (washing and frying in the sun). The removable top cover allows you to conveniently attach a simple “apron” (a piece of vinyl chloride film). In the powder closet booth there should be another box or other container with peat, ash or sawdust.

Flat slate toilet

Wood, of course, is the most affordable and technologically advanced material, but if for other buildings (garage, outbuilding) it is planned to use an asbestos-cement slab (flat slate), then it is also suitable for a toilet booth.

To work with asbestos-cement slab, you will need an electric cutting machine (grinder) equipped with a stone abrasive or diamond cutting disc. Asbestos cement sheets 8-10 mm thick are cut to form the front, back and both side walls of the toilet booth (similar to Figure 2 above). These walls are assembled with screws using frame boards, and then installation is carried out in the same way as described above. In this case, the door leaf is also made from an asbestos cement sheet mounted on a wooden frame, which is used for inserting hinges, locks and other mounting devices.

For convenience and safety of using products made from asbestos cement sheets, it is advisable to cover them with film-forming compounds (varnish, drying oil, paint, etc.).

Video

DIY country toilet

5domov.ru

What kind of toilet to make at the dacha

Before starting construction, you need to choose the type of country toilet. It's not about the house, but about it internal structure. Based on the type of device, they can be divided into two large groups: with or without a cesspool. If the groundwater level in the area is high - higher than 3.5 meters - your choice is limited only to toilets without a cesspool, otherwise waste products will inevitably end up in the water. Similar restrictions are imposed on areas in which there are natural cracks at the base, as well as on shale rocks. On other soils with deeper aquifers, a booth of any design can be installed.

With cesspool

When choosing this option, you need to take into account that the depth of the pit should be 1 meter less than the most high level groundwater (usually spring). Its volume is selected depending on the frequency of visits and the number of people. For example, in permanent residences for 2-3 people, a volume of 1.5 cubic meters is sufficient. For dachas visited mainly on weekends, the cesspool for the toilet may be smaller.

The container can have any shape, but most often it is square, sometimes round. The walls are made of brick, concrete, rubble masonry, and tarred wood. You can make a container from concrete rings. Only in this case will you need to worry about the tightness of the joints and the bottom.

To ensure tightness, a layer of compacted clay (clay castle) 20-30 cm thick is made under the masonry and on the sides. If you are reluctant to bother with compacting clay, you can coat the finished masonry with impregnation, which gives the materials an increased degree of waterproofing (bitumen or cement-based).

A cesspool toilet for a summer residence must be equipped with a ventilation system. A pipe is built into the hole large diameter(at least 100 mm), the second end of which rises at least 50-70 cm above the roof of the house (or house). Also, a ventilation window is made in the house itself. It can be on the door or on one of the side walls.

When more than 2/3 of the volume is filled, the contents of the pit are pumped out using a sewer truck. When planning a toilet for your dacha with your own hands, take into account that a car must drive up to the pit.

There are two types of cesspool organization:

- The usual one is under the house.

- Backlash closet - the pit is located to the side. With this structure, the toilet can stand in the house, and sewage through pipes laid at a certain slope enters the container.

Building a backlash closet in a dacha is a very expensive undertaking, unless you decide to build an extension anyway or your dacha is a full-fledged residential building in which you spend a lot of time. You will need a full ventilation system, water for flushing, and pipes will need to be laid below the freezing depth of the soil. And since they must go at an angle, the cesspool sinks to a decent depth.

When installing a toilet of this type, it is important to maintain the slope of the pipe - it should be 2-3 cm per meter. There is no need to do more or less - exactly in this range. If you make the slope smaller, there is a risk that the contents will stagnate. If you do more, the water will run away, and solid and heavier inclusions will remain in the pipe and will spread “odors.”

Read about methods for eliminating odors in an outdoor pit toilet here.

Without cesspool

In most cases, toilets without a cesspool are much easier and faster to build. In them, waste is collected in an airtight container, which is usually placed directly under the toilet seat. The whole difference is in how the waste is processed and its odor is neutralized. There are the following types:

- Powder closet. In the booth there is also a container with peat, ash, sawdust, earth or a mixture of these components. After visiting the toilet, the waste is covered with a layer of this powder - powdered. Hence the name.

- Peat toilet. This is a type of powder closet. But only crushed peat is used for powdering. There are also industrial-made peat toilets. They are very similar to the usual apartment toilets with a cistern. But the tank contains not water, but peat crumbs. After visiting the toilet, you need to turn the handle on the tank several times, from where peat will fall out.

- Bio toilet. The waste falls into a container filled with a solution containing microorganisms that process it. These booths can often be seen as outdoor toilet in cities. Dry toilets are sold both together with plastic cubicles, and separately - just a toilet with a container.

- Chemical toilet. The recycling principle is the same as in a dry closet, only they use chemicals rather than microorganisms. They are usually available in powder or tablet form. Waste processed in this way cannot be used as fertilizer. They must be periodically drained into the sewer.

The advantages of country toilets without a cesspool (also called dry) are significant:

- you don’t need to dig a hole and fuss with sealing it;

- no need to call a vacuum cleaner (pay for it) and organize access for the car;

- built quickly;

- recycled waste can be used as fertilizer.

There are also significant disadvantages:

- Factory-made toilets are not that cheap.

- It is necessary to periodically change the container.

- It is necessary to monitor the availability of neutralization means.

Read how to make an inexpensive but beautiful path to the toilet here.

Standards for installing a toilet on the site

Most of the restrictions apply to pit toilets: it is necessary to limit possible contamination. The rules are:

- To the source of water - lake, river, well, borehole, etc. - must be at least 25 meters. This also applies to sources located in neighboring areas.

- At least 12 meters to the basement or cellar.

- The nearest inhabited building - shower, bathhouse - is at least 8 meters away.

- At least 4 meters away from buildings where animals are kept.

- The nearest trees should be 4 meters away, bushes - 1 meter.

The remaining standards are valid for all types of toilets:

- There must be at least 1 meter to the site boundary.

- Doors should not open towards the neighboring area.

- When choosing a location, you need to take into account the prevailing wind direction.

When choosing a place where you will build a toilet for your dacha with your own hands, pay attention not only to your own buildings and objects, but also to those of your neighbors. This will help avoid friction with them and with the sanitation station.

If you are building a toilet with a cesspool, you will need to add to all the listed requirements - the organization of an entrance for a sewer truck.

Construction country shower described in this article.

How to make a toilet in the country with your own hands

You have already completed the first two steps: you have chosen the type of toilet and the place to install it. The next step is to choose the sizes. Deciding on them is not so difficult. They told us how to choose the volume of a cesspool - 1.5 cubic meters is enough for 2-3 people, now about what size the toilet house should be. It all depends on own desire and on the size of the owners. In the standard version, toilets are made in the following sizes:

- height - 220 cm;

- width - 150 cm;

- depth - 100 cm.

These dimensions are convenient for people with average build. They can be changed as you wish. There are no standards.

Toilet houses are most often made of wood. But this is not the rule. It can be made of sheet material such as fiberboard, gypsum fiber board, flat slate, brick and any other building materials, profiled sheet metal, even plastic.

Most lovely roofing material for a country toilet - slate. The installation of a soft roof made of fused materials is inexpensive. In general, you can use any available one. It is attached to a continuous sheathing, so there is not much difference.

Building a village toilet

The last stage is the actual construction. The procedure is determined by what type of toilet you will build. If there is a cesspool, this is done first.

Cesspool for toilet

The procedure for construction is as follows:

- A pit is dug in the selected location. Its dimensions are 30-40 cm larger than the planned dimensions of the cesspool.

- At the bottom, 20-30 cm of clay diluted to a paste is placed and compacted: a clay castle is made that will prevent sewage from penetrating into the soil. Therefore, lay layers without voids.

- Lay out the bottom and walls of the pit from brick, rubble, or thick boards impregnated with resin. The main thing is that the walls do not allow moisture to pass through: it should not enter either inside or from the inside. Therefore, waterproofing measures are necessary. Therefore, it is advisable to plaster the walls of the cesspool and then coat them with hydrophobic impregnation. Only one that can withstand aggressive environments.

- The gap between the erected walls and the ground is filled with soaked clay - and then a clay castle is made. This is external waterproofing.

- The ceiling is laid on top of the pit. It is usually made from boards (at least 40 mm thick). There should be two holes in the ceiling - one for installing a toilet seat, the second for organizing a hatch. The hatch for pumping out is usually made double so that unpleasant odors do not penetrate.

- Install the ventilation pipe.